A4 Cabriolet Mk2

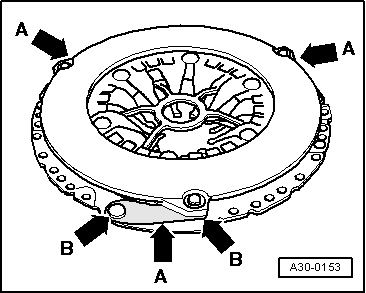

| Servicing conventional clutch - exploded view |

| l | The gearbox has to be removed before working on the clutch → Chapter. |

| 1 - | Flywheel/dual mass flywheel |

| q | Ensure that dowel pins fit tightly |

| q | Contact surface for clutch lining must be free of grooves, oil and grease |

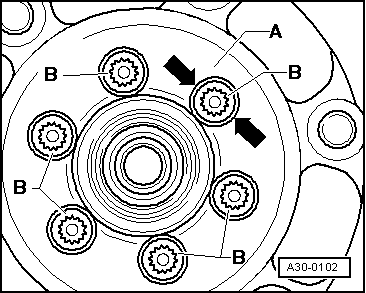

| q | Note instructions when removing weight-optimised dual-mass flywheel → Fig. |

| q | Removing and installing: see corresponding Workshop Manual → Rep. Gr.13 |

| 2 - | Bolt |

| q | For flywheel |

| q | Tightening torque for bolt length 22.5 mm: 60 Nm + 90° further |

| q | Tightening torque for bolt length 43 mm: 60 Nm + 180° further |

| q | Renewing → Rep. Gr.13 |

| 3 - | Clutch plate |

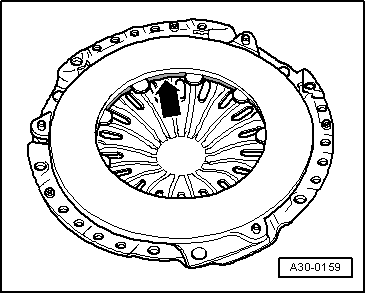

| q | Installation position: |

| q | Coil springs (damper assembly) point towards pressure plate and gearbox |

| q | Clutch lining must make full contact with flywheel |

| q | The marking “Getriebeseite” (gearbox side), if provided, faces towards pressure plate/gearbox |

| q | Select diameter of clutch plate according to engine code → Electronic parts catalogue |

| q | Centralising → Chapter |

| q | Lightly grease splines → Anchor |

| 4 - | Thrust plate |

| q | Removing and installing → Chapter |

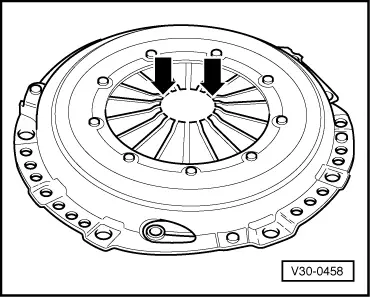

| q | Checking ends of diaphragm spring → Fig. |

| q | Checking spring connection and rivets → Fig. |

| q | Checking wire ring → Fig. |

| 5 - | Bolt |

| q | 22 Nm |

| q | Loosen or tighten in small steps of 90° (1/4 turn) at a time |

| 6 - | Needle bearing |

| q | Check for damage or wear |

| q | Removing and installing: see corresponding Workshop Manual → Rep. Gr.13 |

Note

Note

|

|

Note

Note

|

|

|

|