A4 Cabriolet Mk2

| Dismantling and assembling differential |

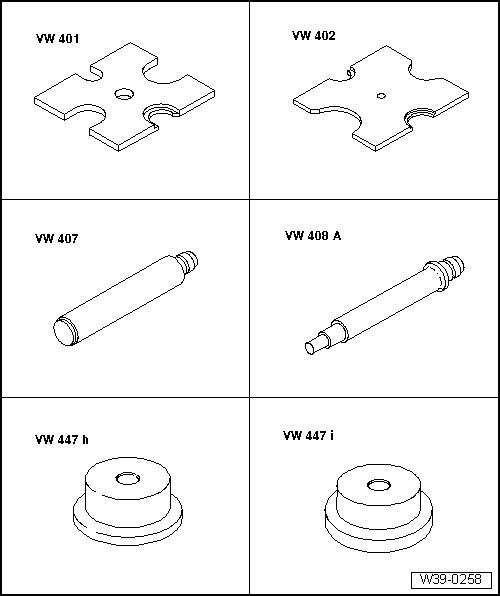

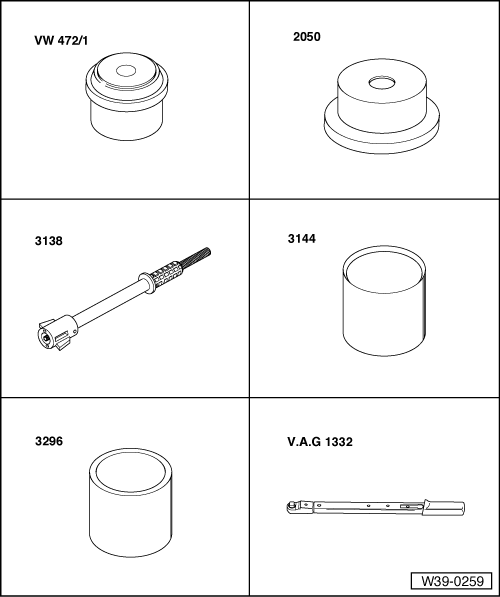

| Special tools and workshop equipment required |

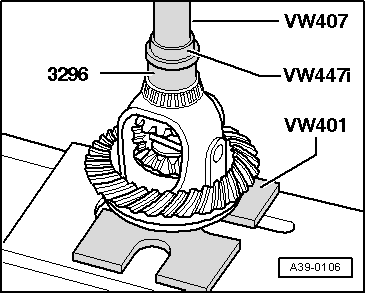

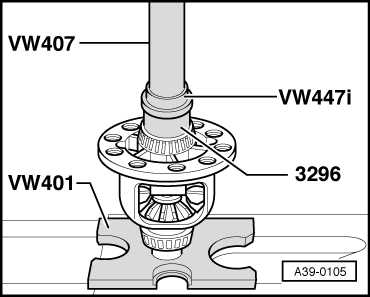

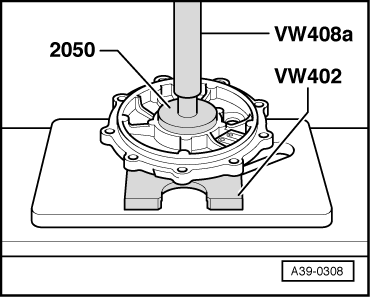

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

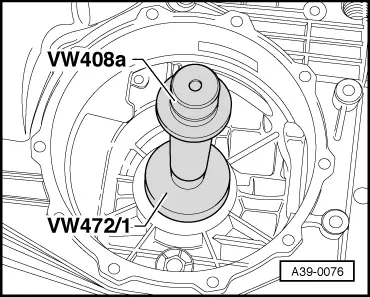

| t | Press tool -VW 408 A- |

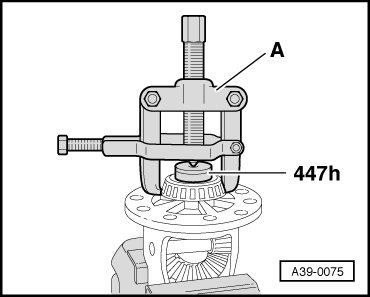

| t | Thrust plate -VW 447 H- |

| t | Thrust plate -VW 447 i- |

| t | Press tool -VW 472/1- |

| t | Thrust piece -2050- |

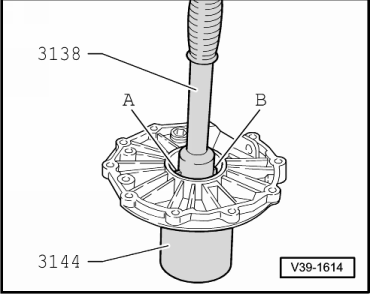

| t | Drift -3138- |

| t | Sleeve -3144- |

| t | Tube -3296- |

| t | Torque wrench -V.A.G 1332- |

| t | Removal and installing tool -VW 459- |

| t | -1-Internal puller -Kukko 21/7- |

| t | -4-Counter-support -Kukko 22/2- |

| t | -3-Puller -Kukko 204/2- |

| t | Two-arm puller -Kukko 44/2- |

Note

Note| t | Removing and installing differential → Chapter |

| t | Always renew both tapered roller bearings together. |

| t | Adjustment work is required when renewing the parts marked with 1) → Chapter. |

| 1 - | Gearbox housing 1) |

| 2 - | Shim “S2” |

| q | Note thickness |

| q | Table of adjustments → Chapter |

| 3 - | Outer race for tapered roller bearing (right-side) 1) |

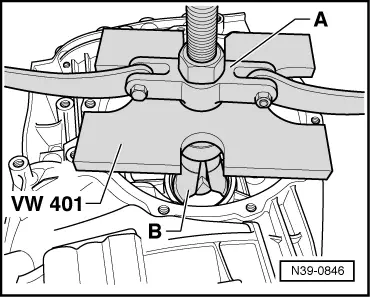

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 4 - | Inner race for tapered roller bearing (right-side) 1) |

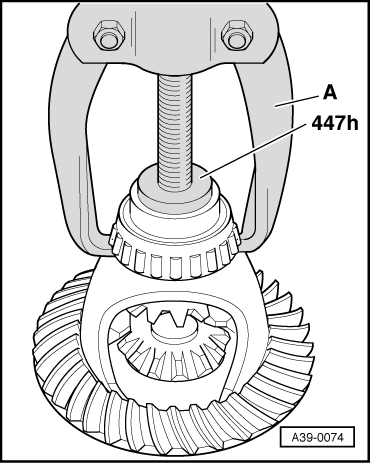

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

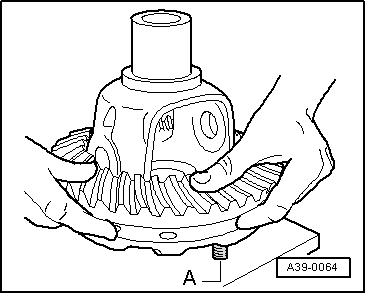

| 5 - | Crown wheel1) |

| q | Is paired with pinion shaft (final drive gear set) |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue → Chapter |

| q | Drive crown wheel off differential cage using a punch → Fig. |

| q | Fitting on differential cage → Fig. |

| 6 - | Differential cage1) |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue → Chapter |

| 7 - | Bolt |

| q | 60 Nm and turn 45° further |

| q | Always renew |

| q | Lightly tighten bolts then tighten in diagonal sequence to correct torque |

| 8 - | Inner race for tapered roller bearing (left-side) 1) |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| q | For correct version, refer to → Electronic parts catalogue |

| 9 - | Speedometer drive wheel |

| q | Removing and installing → Chapter |

| q | Fit the drive wheel carefully onto the differential, making sure that it is kept straight. Do not use force; the drive wheel can break easily. |

| q | Not fitted from 07.02 onwards |

| 10 - | Outer race for tapered roller bearing (left-side) 1) |

| q | Driving out → Fig. |

| q | Pressing in → Fig. |

| q | For correct version, refer to → Electronic parts catalogue |

| 11 - | Shim “S1” |

| q | Note thickness |

| q | Table of adjustments → Chapter |

| q | For correct version, refer to → Electronic parts catalogue |

| 12 - | Cover for final drive 1) |

| q | Coat sealing surfaces lightly with sealing paste -AMV 188 001 02- |

| q | For correct version, refer to → Electronic parts catalogue |

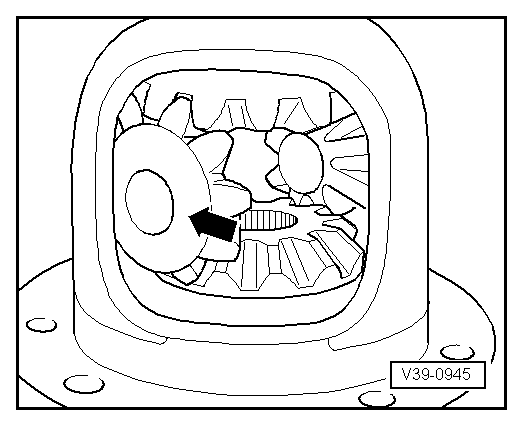

| 13 - | Sun wheel |

| q | Installing → Fig. |

| 14 - | Differential pinion pin |

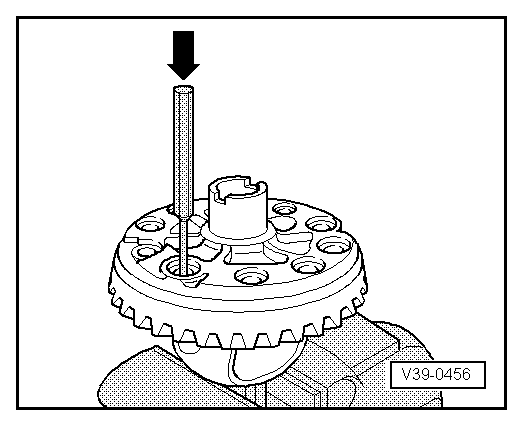

| q | Drive out with drift after removing spring pin |

| 15 - | Spring pin |

| q | Secures differential pinion pin |

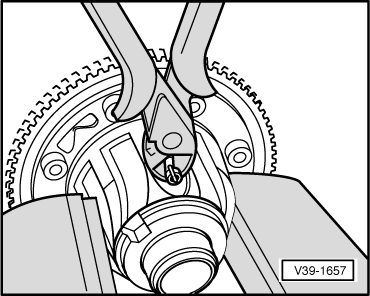

| q | Version with annular groove: removing and installing → Fig. |

| q | Version without annular groove: knock out with drift |

| 16 - | Planet pinion |

| q | Installing → Fig. |

| 17 - | One-piece thrust washer |

| q | Lubricate with gear oil before installing |

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING