| t

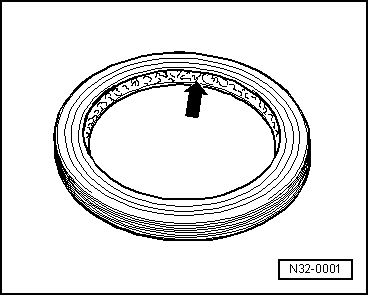

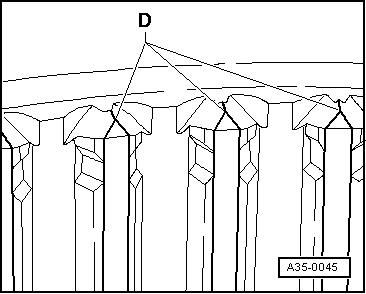

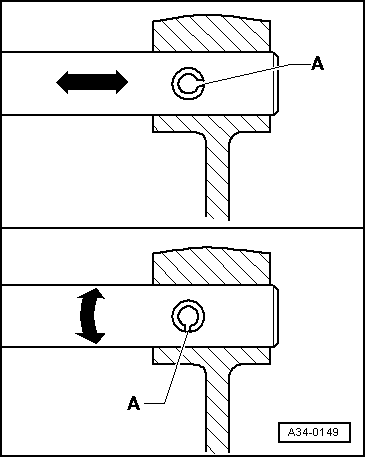

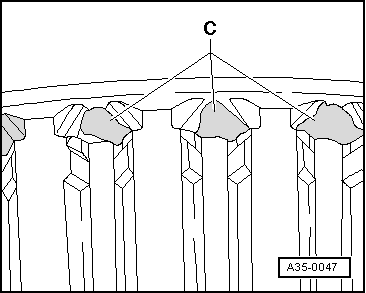

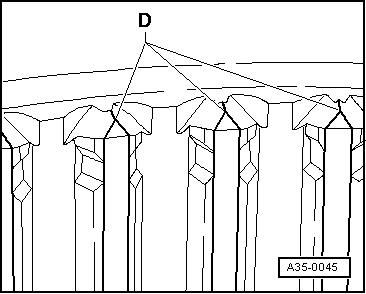

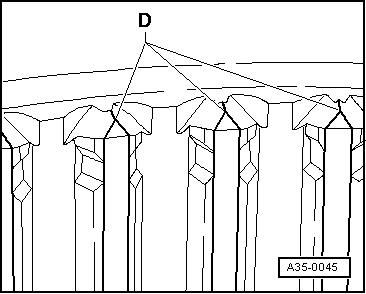

| In comparison: intact locking collar: |

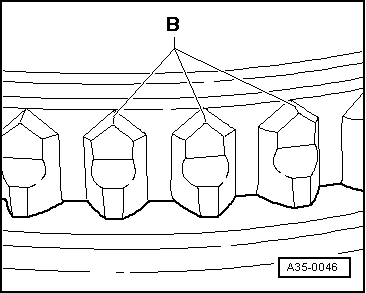

| D - | Intact internal splines on locking collar |

| t

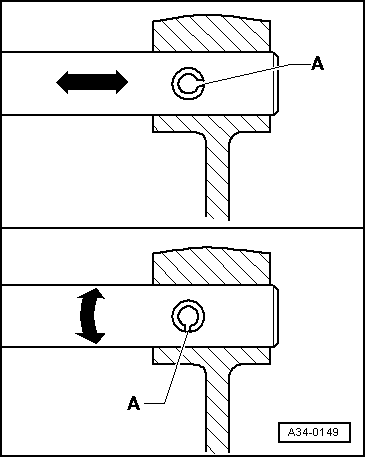

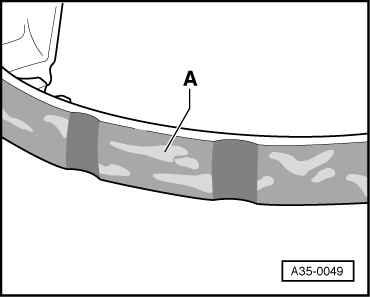

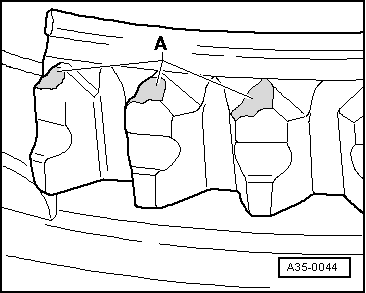

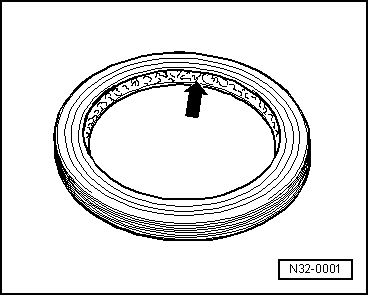

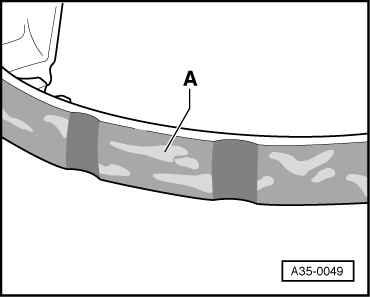

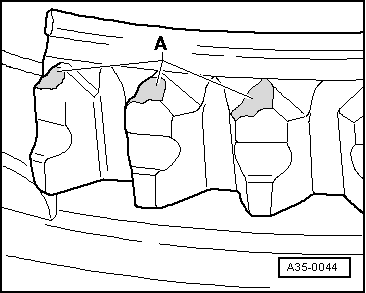

| Always renew synchro-rings with carbon coating together with locking collar. Renew selector gears also if there are traces of wear. |

| t

| When removing gearbox, remove clutch slave cylinder without disconnecting pipes. |

| t

| Do not depress the clutch pedal after removing the clutch slave cylinder if the hydraulic pipe is still connected. Otherwise, the piston will be pressed out of the slave cylinder and be destroyed. |

| t

| After installing the slave cylinder carefully press the clutch pedal. If you feel an unusually strong point of resistance when depressing the clutch pedal, you must not press it down further. The plunger of the slave cylinder is likely to have been guided past the clutch release lever. The slave cylinder would then be destroyed once pedal force exceeds approx. 300 N. |

| t

| Ensure that the pressure plate is kept straight: loosen and tighten bolts consecutively in steps of 90° (1/4 turn each). |

| t

| On vehicles with SAC pressure plate an adjuster ring has to be reset when only the clutch plate is renewed → Chapter. |

| t

| Note assembly instructions for SAC pressure plate → Chapter. |

| t

| Before renewing the master or slave cylinder on the assumption that it is defective you must first carry out a function check → Chapter. |

| t

| If the clutch pedal does not return all the way to its initial position after releasing it (clutch pedal in rest position), you must bleed the clutch system (further measures → Chapter). The clutch system should be bled at the same intervals as the brake system → Booklet45. |

| t

| If the clutch has burnt out, thoroughly clean the clutch housing, flywheel and parts of the engine facing the gearbox in order to prevent odour. |

|

|

|