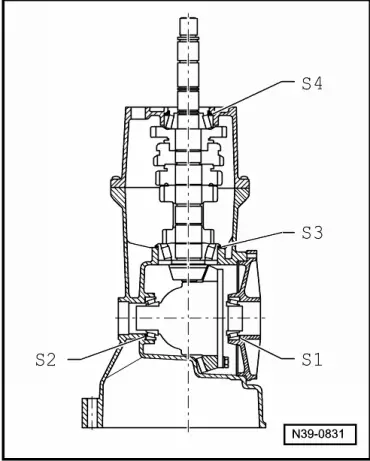

| Adjusting pinion shaft and crown wheel |

| t

| Careful adjustment of the crown wheel and pinion shaft is essential to ensure that the final drive gives long service and runs silently. For this reason, the pinion shaft and crown wheel are matched together during manufacture, and checked to ensure a good mesh pattern and quiet running in both directions of rotation. The position of quietest running is found by moving the pinion shaft in an axial direction and at the same time lifting the crown wheel out of the zero-play mesh position by the amount necessary to maintain the backlash within the specified tolerance. |

| t

| The deviation, or tolerance “r”, which is related to the master gauge “Ro”, is marked on the outer circumference of the crown wheel. Only renew gear set (crown wheel and pinion shaft) together! |

|

|

|

Note

Note