| –

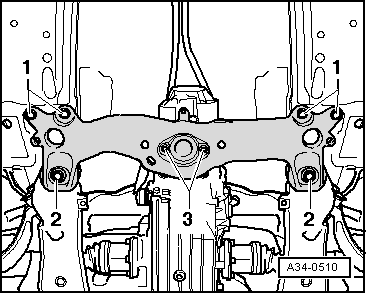

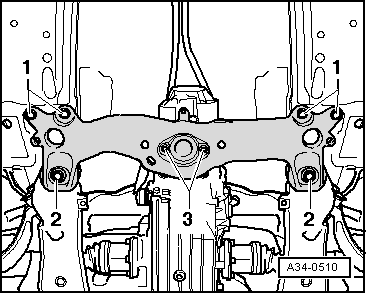

| Bolt tunnel cross member onto gearbox mounting -3-. |

| –

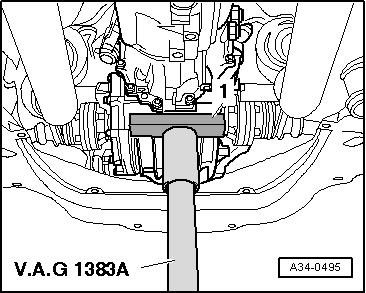

| Raise gearbox using engine and gearbox jack -V.A.G 1383 A- and secure tunnel cross member to body using bolts -1- and -2- → Rep. Gr.40. |

| –

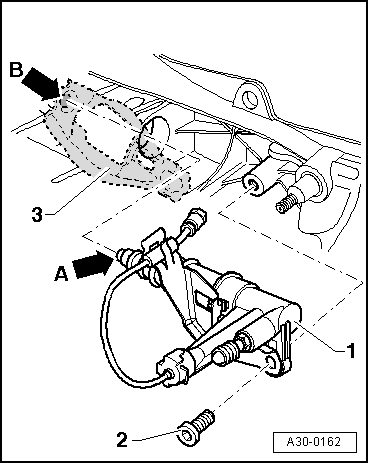

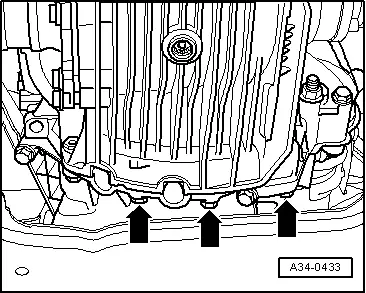

| Install exhaust system and align it so it is stress-free → Rep. Gr.26. |

| –

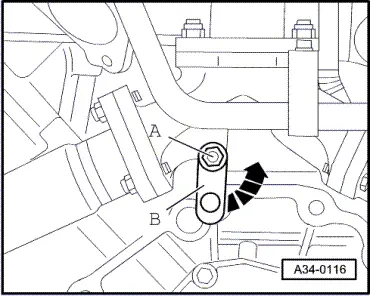

| Check selector mechanism for correct adjustment, and re-adjust if necessary → Chapter. |

| –

| Check oil level in manual gearbox → Chapter. |

| –

| Follow the steps required after connecting the battery → Rep. Gr.27. |

Note | t

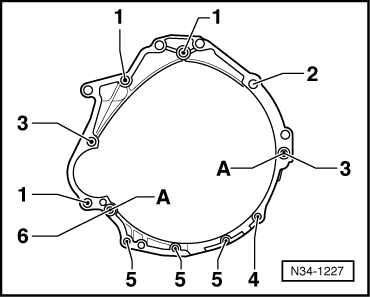

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricant such as engine or gearbox oil may be used, but do not use graphite lubricant. |

| t

| Do not use parts which have been degreased. |

| t

| Tolerance for tightening torques ±15 %. |

|

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution