| –

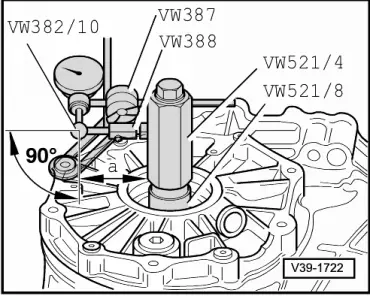

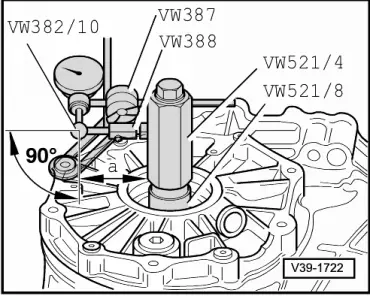

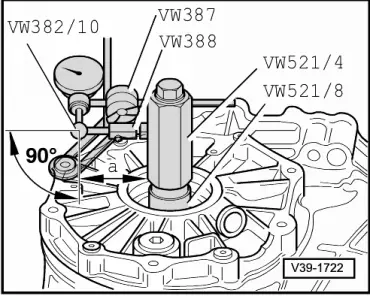

| Set up measuring tools with dial gauge extension -VW 382/10- (6 mm, flat) as shown in the illustration. |

| –

| Set measuring lever, adjustable -VW 388-. |

| –

| Measure backlash between faces of gear teeth as follows: |

| –

| Turn crown wheel until it makes contact with the face of one tooth (end of backlash travel). |

| –

| Set dial gauge to “0” with a preload of 2 mm. |

| –

| Turn back crown wheel until it makes contact with opposite face (backlash). |

| –

| Take backlash reading and note down measured value. |

| –

| Turn crown wheel through 90° and repeat measurements another 3 times. |

Note | If the individual measurements differ from each other by more than 0.06 mm, the installation of the crown wheel or the final drive gear set itself is not correct. Check installation; renew final drive gear set if necessary. |

| Determining average backlash |

| –

| Add the 4 measured values together and divide by 4. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note