A4 Cabriolet Mk2

| Removing gearbox - vehicles with V6 petrol engine |

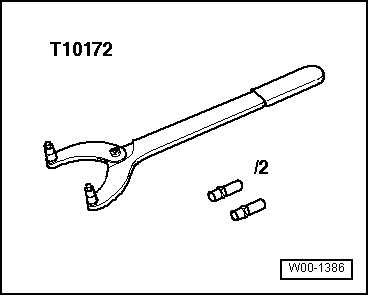

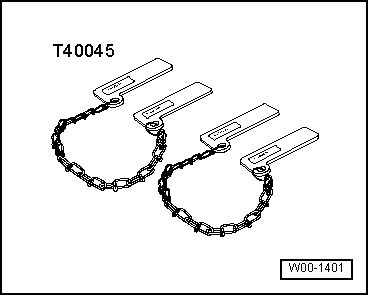

| Special tools and workshop equipment required |

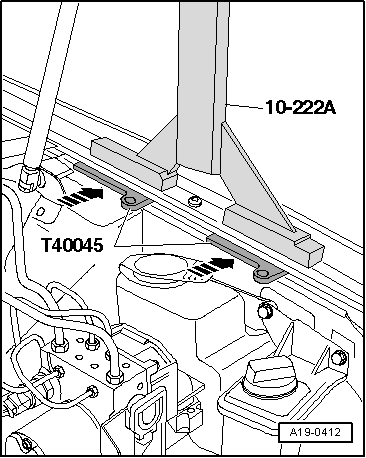

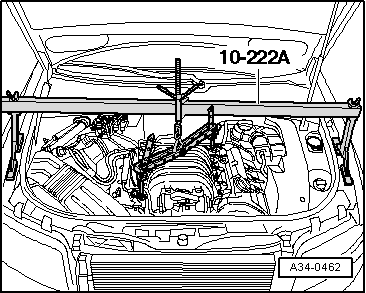

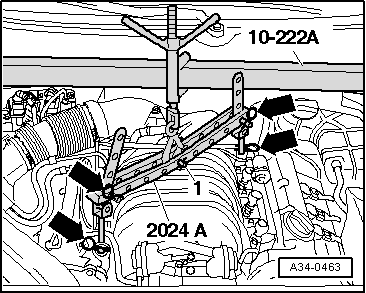

| t | Support bracket -10-222 A- |

| t | Lifting tackle -2024 A- |

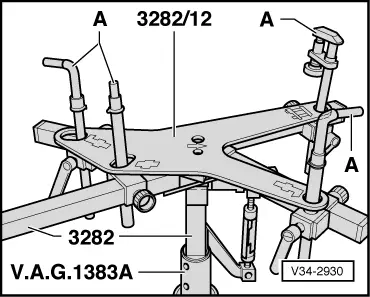

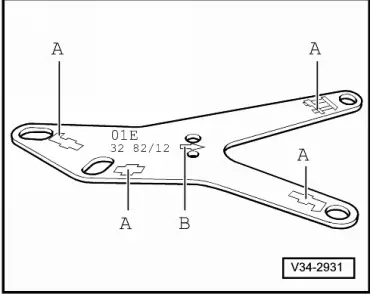

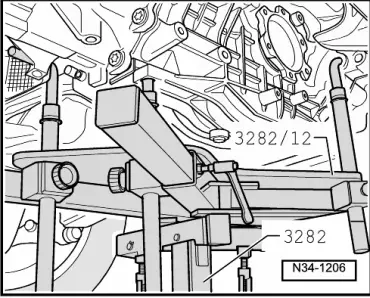

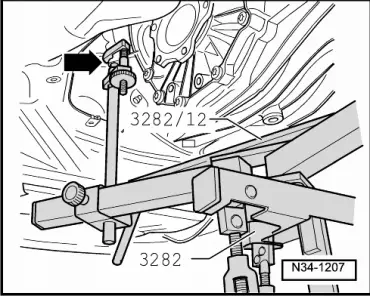

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/12- |

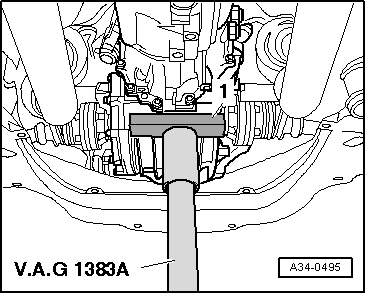

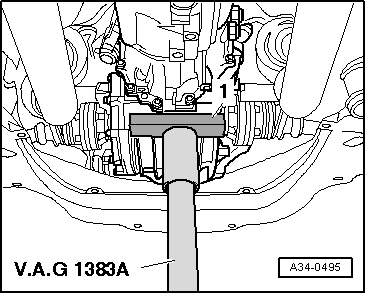

| t | Engine and gearbox jack -V.A.G 1383 A- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note |

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Caution

Caution WARNING

WARNING