A4 Cabriolet Mk2

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

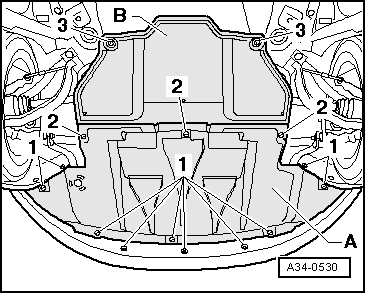

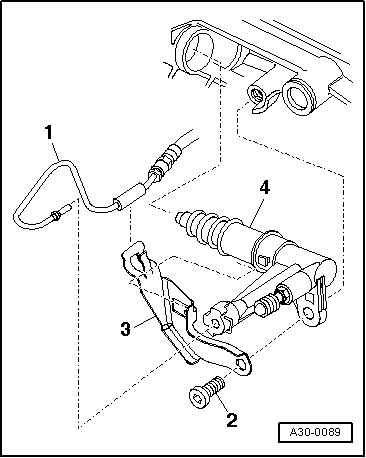

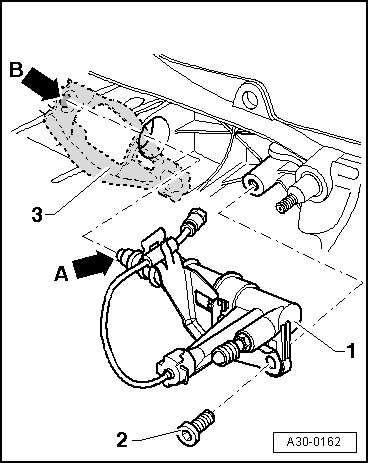

| Component | Nm | ||||

| Slave cylinder to gearbox | 23 1) | ||||

| Gearbox selector lever to selector shaft | 20 2) | ||||

| Heat shield for drive shaft to gearbox | 23 | ||||

| |||||

Caution

Caution