| –

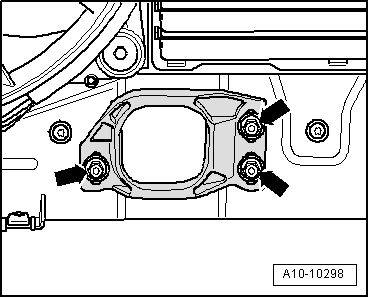

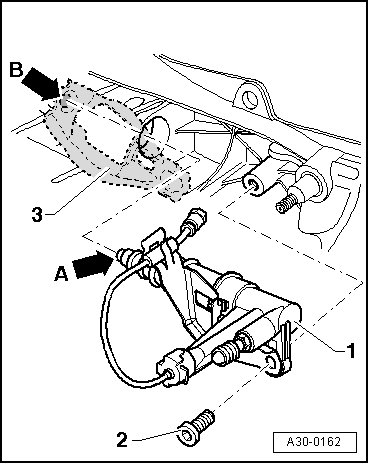

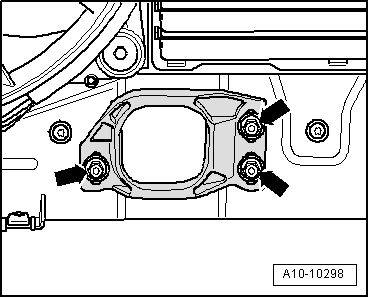

| Loosen bolts -arrows- for torque reaction support. |

| –

| Allow stop for torque reaction support to settle on rubber buffer for torque reaction support under its own weight and re-tighten bolts. |

| The remaining installation steps are carried out in the reverse sequence; note the following points: |

Caution | Never use a charger to aid starting. Otherwise, the vehicle's control units could be damaged. |

|

Note | t

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricant such as engine or gear oil may be used, but do not use graphite lubricant. |

| t

| Do not use parts which have been degreased. |

| t

| Tolerance for tightening torques is ± 15%. |

|

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution