| t

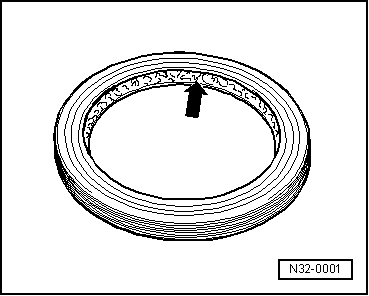

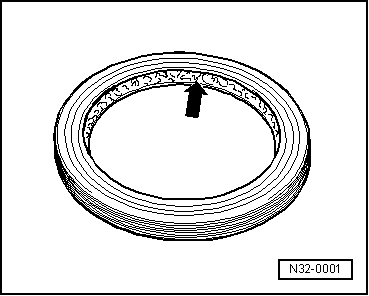

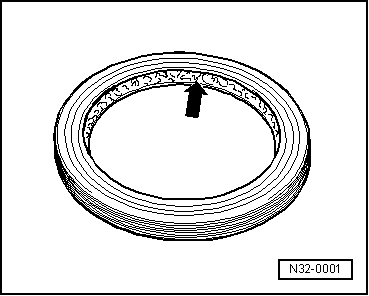

| Before installing oil seals, fill the space between the sealing lips -arrow- half full with sealing grease -G 052 128 A1-. |

| t

| The open side of the oil seals faces toward the side with fluid filling. |

| t

| Before installing, lightly lubricate outer circumference of seal and sealing lips with ATF or gear oil, depending on fitting location. |

| t

| Lightly lubricate O-rings with ATF before installation to prevent them getting crushed during assembly. |

| t

| Use only ATF for parts running in ATF. Other lubricants will cause malfunction of the gearbox hydraulics. |

| t

| When installing a new oil seal, position the seal in the housing so that the sealing lip does not contact the shaft in the same place as the old seal (make use of installation depth tolerances). |

| t

| Renew paper gaskets, clean all sealing surfaces thoroughly and remove previous gaskets completely. |

| t

| Slacken bolts in reverse sequence to the specified tightening sequence. |

| t

| Nuts and bolts which secure covers and housings should be loosened and tightened in diagonal sequence and in stages if no tightening sequence is specified. |

| t

| The tightening torques stated apply to non-oiled nuts and bolts. |

| t

| Always renew self-locking bolts and nuts. |

| t

| Use a wire brush to clean the threads of bolts which are secured with locking fluid. Then apply locking fluid -AMV 185 101 A1- to bolts again before fitting. |

| t

| Threaded holes which take self-locking bolts or bolts coated with locking fluid must be cleaned (using a tap or similar). Otherwise there is a danger of the bolts shearing off the next time they are removed. |

| t

| Do not over-stretch circlips. |

| t

| Always renew circlips which have been damaged or over-stretched. |

| t

| Circlips must be properly seated in the base of the groove. |

| t

| Lubricate bearings with gear oil or ATF, depending on fitting location. |

Caution | t

| Before touching or removing the mechatronic unit, always discharge any static electricity by touching an earthed metal part, such as vehicle earth, a heater radiator or lifting platform with your hand. |

| t

| Never touch the 16 contacts in connector -B- with your hands, as static discharge would damage the control unit and mechatronic unit. |

|

| t

| Renew the gearbox if any of the shift elements are scorched. |

|

|

|