A4 Cabriolet Mk2

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

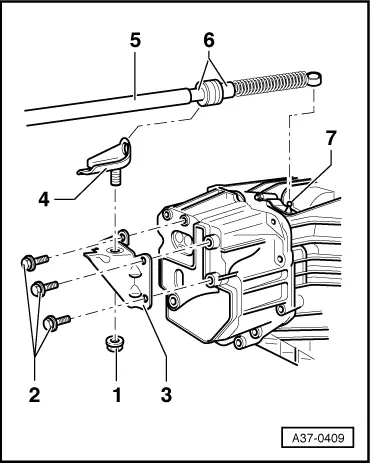

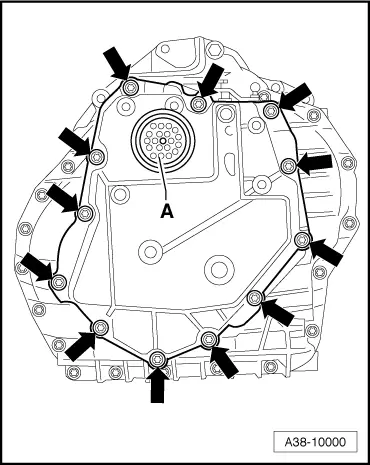

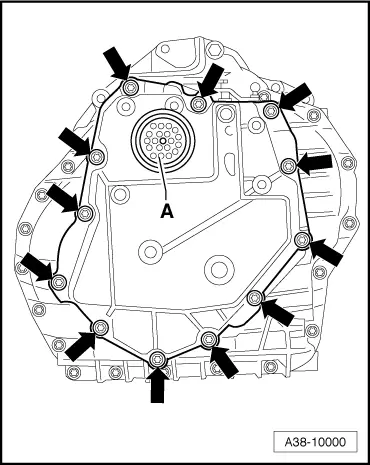

| Component | Nm | ||||

| End cover to gearbox | 15 + 90° 1)2) | ||||

| |||||

WARNING

WARNING