A4 Cabriolet Mk2

Note

Note

|

| Special tools and workshop equipment required |

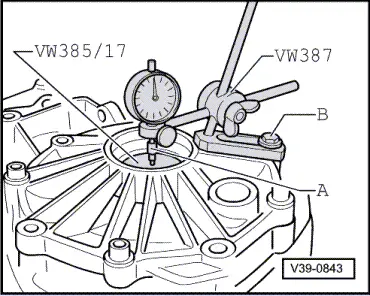

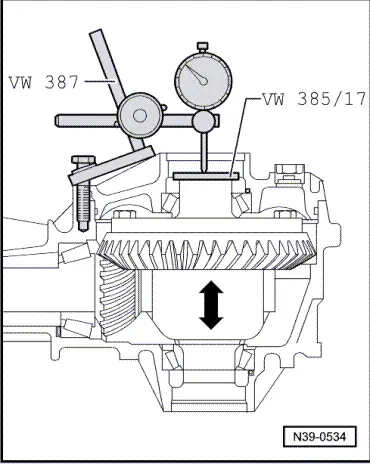

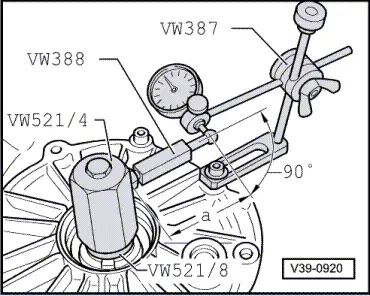

| t | End measuring plate -VW 385/17- |

| t | Universal dial gauge bracket -VW 387- |

| t | Measuring lever -VW 388- |

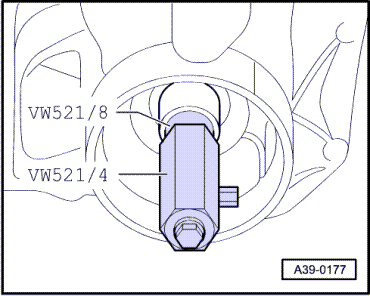

| t | Crown wheel adjusting tool -VW 521- |

| t | Torque wrench -V.A.G 1331- |

| t | Dial gauge |

| t | Hexagon bolt M 8 x 45 |

Note

Note

|

|

|

|

|

|

|

|

|

| Example: | ||

| Inserted shim “S2*” | 1.00 mm | |

| + | Measured value | 0.50 mm |

| + | Bearing preload (constant value) | 0.30 mm |

| = | Total shim thickness “Stotal” for “S1” plus “S2” | 1.80 mm |

Note

Note

|

| Example: | ||

| Total shim thickness “Stotal” for “S1” + “S2” | 1.80 mm | |

| – | Inserted shim(s) “S2*” | 1.00 mm |

| = | Thickness of shim “S1*” | 0.80 mm |

|

| Example: | ||

| 1st measured value | 0.28 mm | |

| + | 2nd measured value | 0.30 mm |

| + | 3rd measured value | 0.30 mm |

| + | 4th measured value | 0.28 mm |

| = | Sum of measured values | 1.16 mm |

Note

Note

|

| Example: | ||

| Inserted shim(s) “S2*” | 1.00 mm | |

| – | Average backlash | 0.29 mm |

| + | Lift (desired average value for backlash) | 0.15 mm |

| = | Thickness of shim “S2” | 0.86 mm |

|

| Example: | ||

| Total shim thickness “Stotal” for “S1” plus “S2” | 1.80 mm | |

| – | Thickness of shim “S2” | 0.86 mm |

| = | Thickness of shim “S1” | 0.94 mm |

|

Note

Note

|

|