A4 Cabriolet Mk2

| Renewing oil seal for propshaft flange on rear final drive (rear final drive installed) |

Note

Note| Original flange for propshaft must be re-installed. |

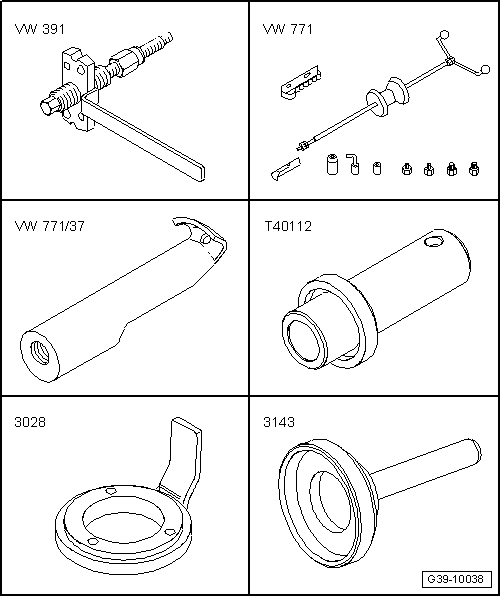

| Special tools and workshop equipment required |

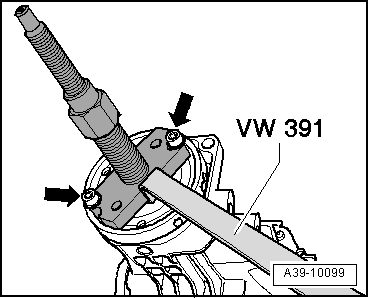

| t | Drive flange installing tool -VW 391- |

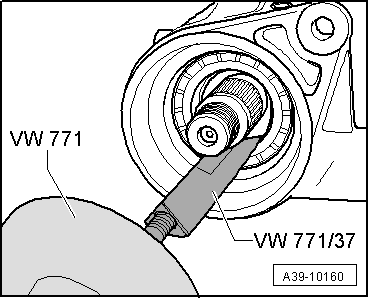

| t | Multi-purpose tool -VW 771- |

| t | Extractor tool -VW 771/37- |

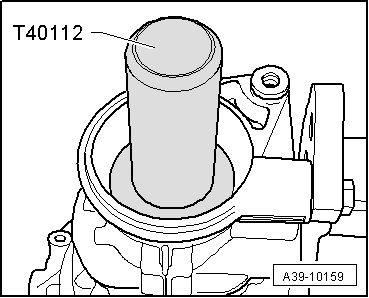

| t | Thrust piece -T40112- |

| t | Counterhold tool -3028- |

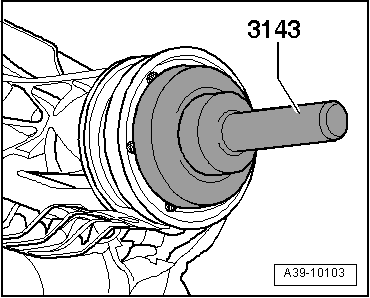

| t | Drift sleeve -3143- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution