| t

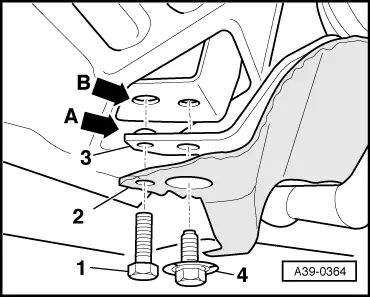

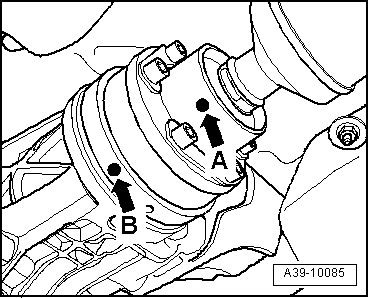

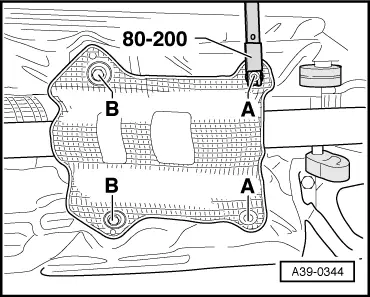

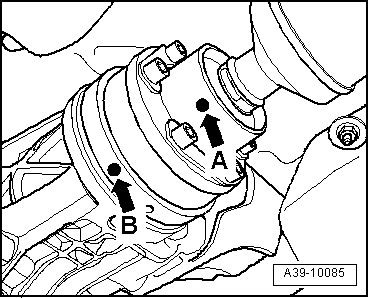

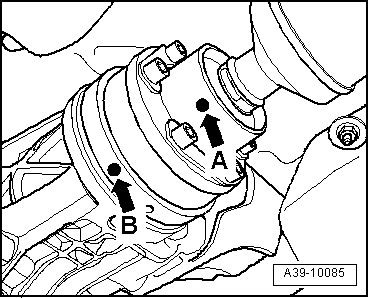

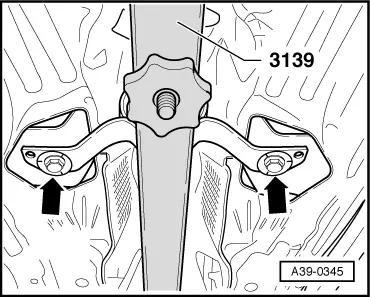

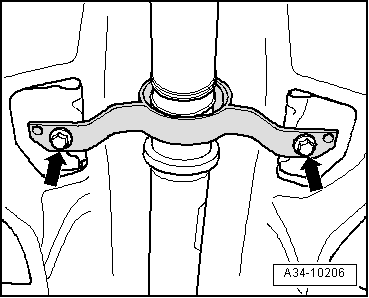

| Make sure that the marks on the propshaft flange -arrow A- and on the gearbox/final drive flange -arrow B- are in line. |

| t

| If a new propshaft is being installed and the factory marking on the rear final drive flange is no longer visible, the radial run-out at the flange for the propshaft must be measured → Chapter, and the coloured marking on the new propshaft must be aligned with the new marking on the flange. |

| –

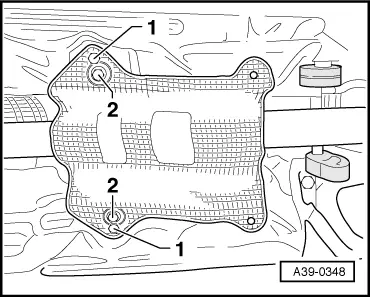

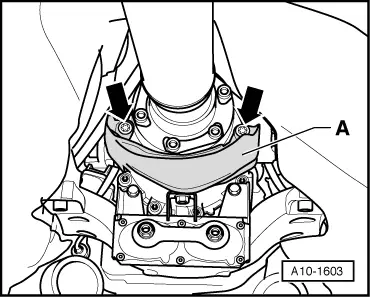

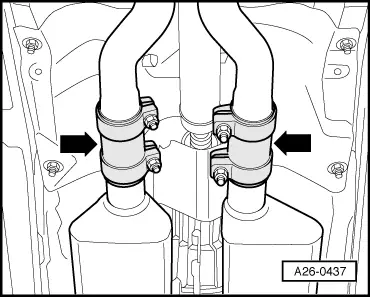

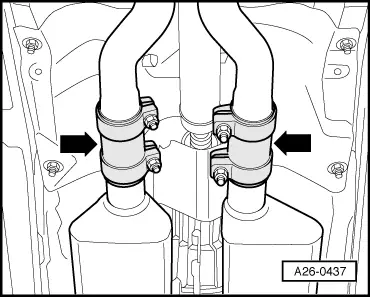

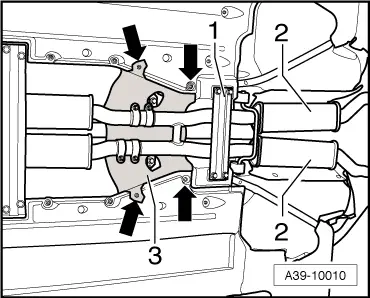

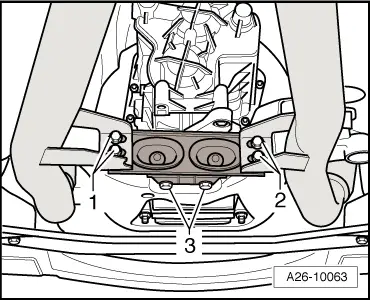

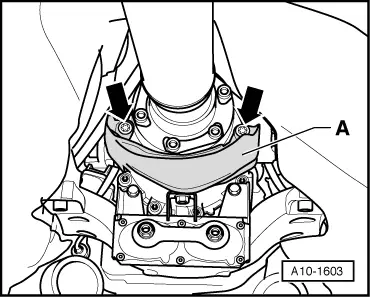

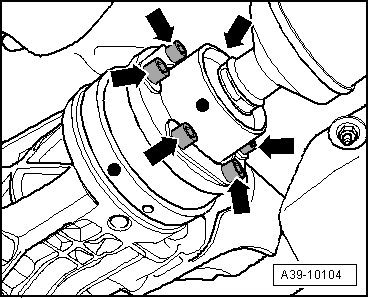

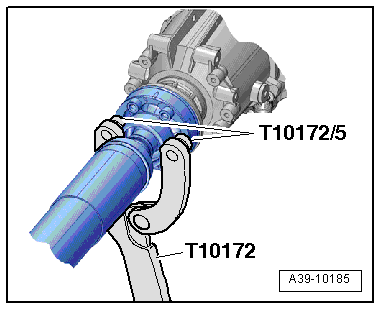

| Gaskets for propshaft on flanges of gearbox and rear final drive must be renewed. Degrease sealing surfaces and glue on new gaskets. |

|

|

|

Note

Note

Note

Note

Note

Note