A4 Cabriolet Mk2

| Removing and installing 1st, 2nd and reverse gear - exploded view |

Note

Note| t | Items 12 and 15 to 22 were modified on 1st and 2nd gear selector rod version with spring-loaded selector fork → Fig.. Refer to → Electronic parts catalogue “(ETKA)” to allocate components. |

| t | Selector gears should have an axial play of min. 0.10 mm after installing. |

| 1 - | Nut, 300 Nm |

| q | Apply locking fluid -AMV 185 101 A1- when fitting |

| q | Slackening → Anchor |

| q | Tightening → Anchor |

| 2 - | Grooved ball bearing |

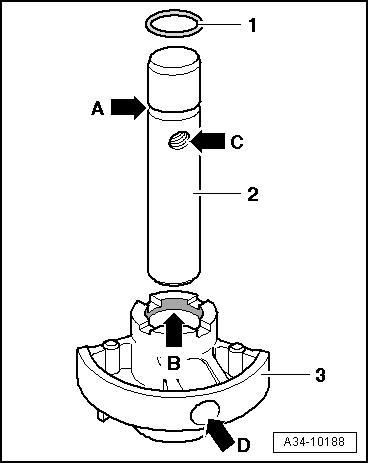

| q | Pull off with clutch unit → Fig. |

| q | Driving on → Fig. |

| 3 - | Washer |

| 4 - | Clutch unit |

| q | Removing and installing → Chapter |

| 5 - | Inner ring for reverse gear |

| q | Installation position → Fig. |

| q | Renew if scored or if there are visible traces of wear |

| 6 - | Intermediate ring for reverse gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| 7 - | Synchro-ring for reverse gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| q | Renew if scored or if there are visible traces of wear |

| 8 - | Reverse selector gear |

| q | With locking collar for reverse gear |

| q | Assembling locking collar and reverse selector gear → Fig. |

| 9 - | Needle bearing |

| q | For reverse gear |

| 10 - | Needle bearing inner race |

| q | For reverse selector gear |

| q | Pull off together with 1st speed selector gear → Fig. |

| q | Driving on → Fig. |

| 11 - | Thrust washer |

| q | For 1st speed selector gear and reverse gear |

| 12 - | 1st speed selector gear |

| 13 - | Needle bearing |

| q | For 1st gear |

| 14 - | Needle bearing inner race |

| q | For 1st speed selector gear |

| q | Pull off together with 2nd speed selector gear → Fig. |

| q | Driving on → Fig. |

| 15 - | Inner ring for 1st gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| q | Renew if scored or if there are visible traces of wear |

| 16 - | Intermediate ring for 1st gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| 17 - | Synchro-ring for 1st gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| q | Renew if scored or if there are visible traces of wear |

| q | Do not interchange with synchro-ring for 2nd gear |

| 18 - | Locking collar/synchronising hub for 1st and 2nd gear |

| q | Assembling locking collar/synchronising hub → Anchor |

| 19 - | Synchro-ring for 2nd gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| q | Renew if scored or if there are visible traces of wear |

| q | Do not interchange with synchro-ring for 1st gear |

| 20 - | Intermediate ring for 2nd gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| 21 - | Inner ring for 2nd gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| q | Renew if scored or if there are visible traces of wear |

| 22 - | 2nd speed selector gear |

| 23 - | Needle bearing |

| q | For 2nd gear |

| 24 - | Gearbox housing |

| q | With input shaft, pinion shaft, differential and selector rods |

| q | Use pin without lug → Item when renewing gearbox housing |

| 25 - | Locking bush |

| q | For 1st and 2nd gear selector rod |

| 26 - | Locking bush |

| q | For reverse gear selector rod |

| 27 - | Bearing mounting |

| q | Supports bearings for input shaft and pinion shaft in gearbox cover |

| 28 - | Mounting for reverse shaft |

| q | Clip into bearing mounting → Item |

| 29 - | Reverse shaft |

| q | With support for reverse shaft |

| q | Assembling reverse shaft and support for reverse shaft → Fig. |

| 30 - | Needle bearing |

| q | For reverse gear wheel |

| 31 - | Reverse gear wheel |

| q | Installation position: teeth face mounting for reverse shaft |

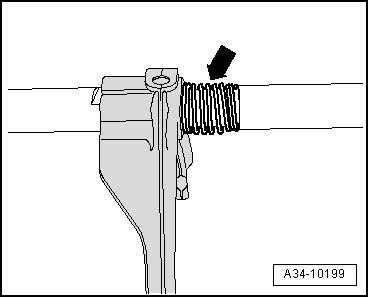

| 32 - | Selector rod for 1st and 2nd gear |

| q | Installation position → Fig. |

| q | Only to be renewed complete with pinned selector fork for 1st and 2nd gear |

| q | Modification: with spring-loaded selector fork → Fig., allocate via → Electronic parts catalogue “ETKA”. |

| 33 - | Reverse gear selector rod |

| q | Installation position → Fig. |

| q | Only to be renewed complete with pinned selector fork for reverse gear |

|

|