A4 Cabriolet Mk2

| Servicing gearbox housing |

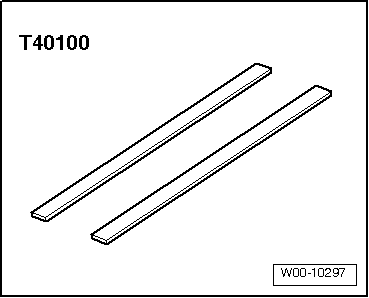

| Special tools and workshop equipment required |

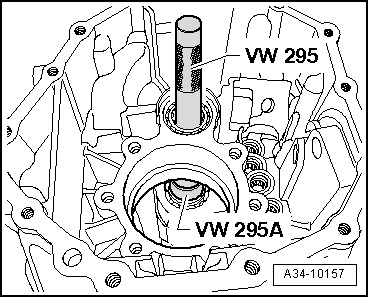

| t | Drift -VW 295- |

| t | Adapter -VW 295 A- |

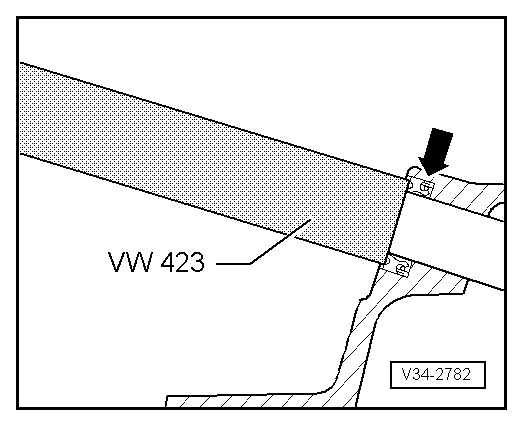

| t | Tube -VW 423- |

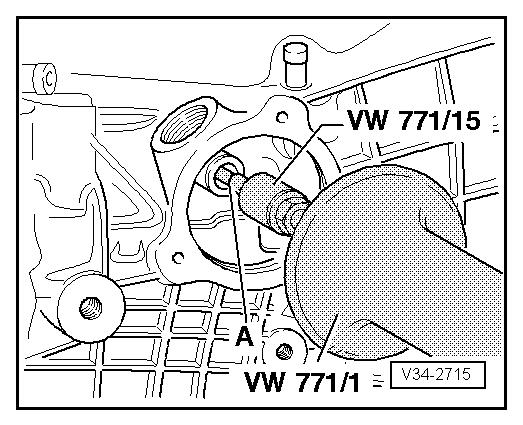

| t | Multi-purpose tool -VW 771- |

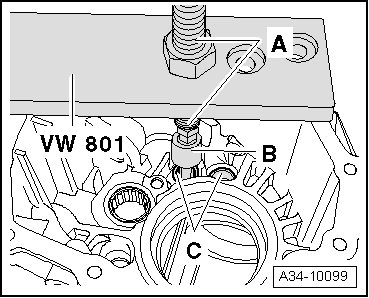

| t | Support plate -VW 801- |

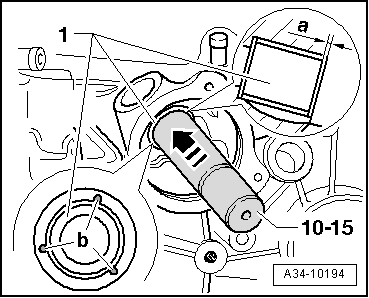

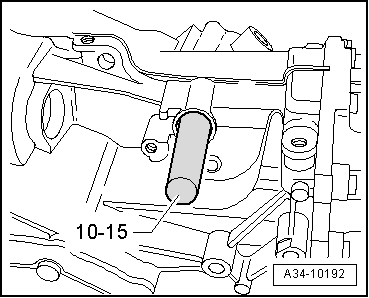

| t | Guide pin -10 - 15- |

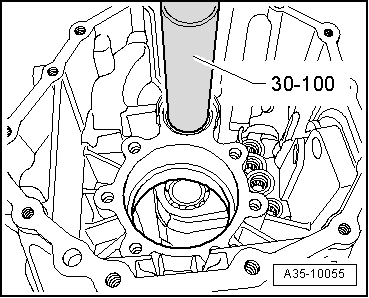

| t | Drift sleeve -30 - 100- |

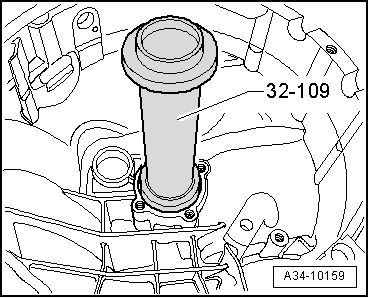

| t | Tube -32 - 109- |

| t | Locking pin -2064- |

| t | Assembly tool -3253- |

| t | Internal puller -3275- |

| t | -1-Internal puller -Kukko 21/2- |

| t | -4-Counter-support -Kukko 22/1- |

| t | -4-Counter-support -Kukko 22/2- |

| t | Depth gauge |

|

|

|

|

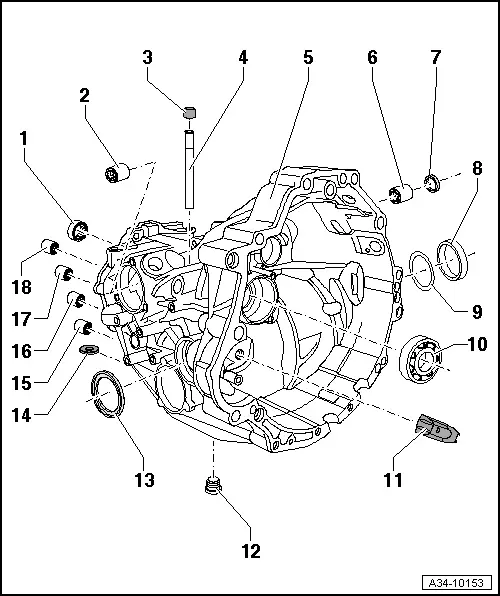

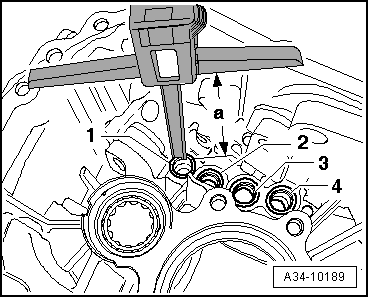

| 1 - | Needle bearing |

| q | For input shaft |

| q | Always renew |

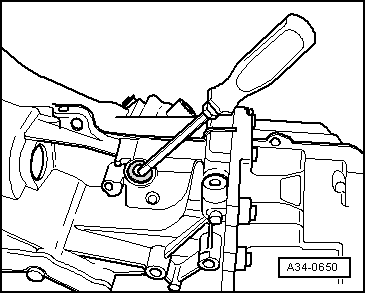

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

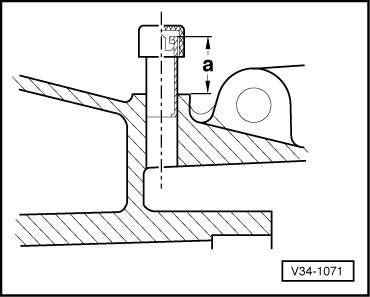

| q | Measuring insertion depth → Fig. |

| q | Peen to secure after installing → Fig. |

| 2 - | Ball sleeve |

| q | For selector shaft |

| q | Pulling out → Fig. |

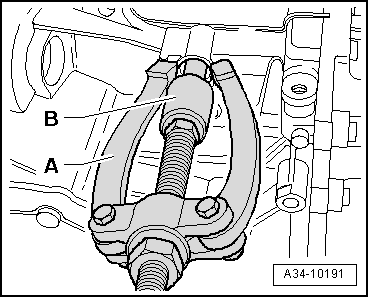

| q | Driving in and securing → Fig. |

| 3 - | Cap |

| q | For gearbox breather |

| 4 - | Breather pipe |

| q | Installation depth → Fig. |

| q | Clip in cap → Item for gearbox breather |

| 5 - | Gearbox housing |

| q | When renewing: re-determine positioning of 2nd speed selector gear → Chapter, adjust pinion shaft and differential (final drive gear set) → Chapter |

| 6 - | Ball sleeve |

| q | For selector shaft |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| 7 - | Oil seal for selector shaft |

| q | Can be renewed with gearbox removed (gearbox remains assembled) → Chapter |

| q | Always renew |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| q | Always use assembly sleeve to fit oil seal (if selector shaft remains installed in gearbox) → Chapter |

| 8 - | Tapered roller bearing outer race (right-side) |

| q | For differential |

| q | If renewed: adjust differential (crown wheel) → Chapter |

| q | Removing and installing → Item |

| 9 - | Shim “S2” |

| q | Note thickness |

| q | Table of adjustments → Chapter |

| 10 - | Grooved ball bearing |

| q | For input shaft |

| q | Removing (gearbox dismantled) → Fig. |

| q | Removing (gearbox removed but not dismantled) → Chapter |

| q | Installing → Fig. |

| 11 - | Intermediate piece |

| q | Renew if damaged |

| 12 - | Oil drain plug, 40 Nm |

| 13 - | Oil seal |

| q | For flange shaft (right-side) |

| q | Renewing → Chapter |

| 14 - | Magnet |

| q | Clean |

| q | Insert in gearbox housing rib |

| 15 - | Ball sleeve |

| q | For reverse gear selector rod |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| q | Measuring insertion depth → Fig. |

| 16 - | Ball sleeve |

| q | For selector rod for 1st and 2nd gear |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| q | Measuring insertion depth → Fig. |

| 17 - | Ball sleeve |

| q | For selector rod for 3rd and 4th gear |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| q | Measuring insertion depth → Fig. |

| 18 - | Ball sleeve |

| q | For selector rod for 5th and 6th gear |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| q | Measuring insertion depth → Fig. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|