| –

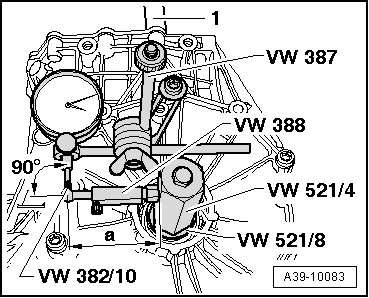

| After installing shims “S1” and “S2”, turn differential 5 turns in both directions so that the tapered roller bearings settle. |

| –

| Measure backlash four times on circumference. |

| t

| Specification: 0.12 ... 0.22 mm |

Note | t

| If the pinion shaft -1- rotates during the measurements, counter-hold pinion shaft to make sure that the measured value of the backlash is correct. |

| t

| Adjustment must be repeated if backlash is outside tolerance. The total shim thickness “Stotal” must remain unchanged. |

| t

| The discrepancy between individual measured values must not exceed 0.06 mm. |

|

|

|

Note

Note

Note

Note Note

Note