A4 Cabriolet Mk2

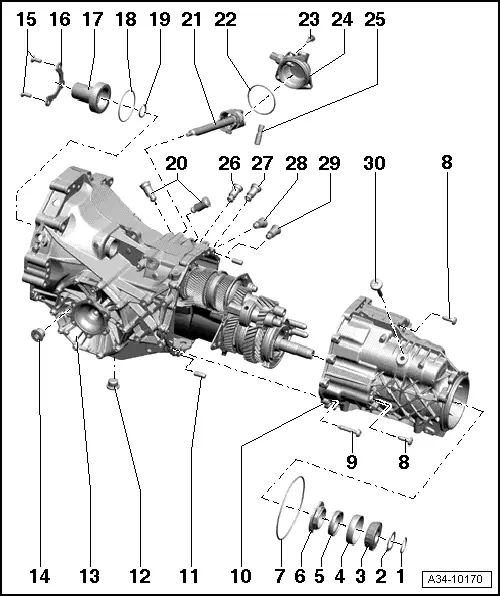

| Removing and installing gearbox cover and selector shaft - exploded view |

Note

Note| t | Removing and installing 1st, 2nd and reverse gear → Chapter |

| t | Removing and installing input shaft, pinion shaft, hollow shaft and selector rods → Chapter. |

| t | Do not interchange locking bushes for selector shaft and selector rods. Apply marking prior to removal. |

| 1 - | Circlip |

| q | Note thickness |

| q | Re-determining thickness → Anchor |

| 2 - | Washer |

| q | Note thickness |

| q | Re-determining thickness → Anchor |

| 3 - | Tapered roller bearing inner race |

| q | Can be removed and installed by hand |

| 4 - | Tapered roller bearing outer race |

| q | Can be removed and installed by hand |

| 5 - | Spacer ring |

| q | Secures 12-point nut → Item on hollow shaft to prevent it from working loose |

| 6 - | 12-point nut, 75 Nm |

| 7 - | O-ring |

| q | Always renew |

| q | Lubricate with gear oil |

| q | Insert in circumferential groove in gearbox cover |

| 8 - | Bolt, 27 Nm |

| q | 2 x |

| q | Self-locking |

| q | Renew |

| 9 - | Bolt, 24 Nm |

| q | 13 x |

| 10 - | Gearbox cover |

| q | Servicing → Chapter |

| 11 - | Dowel pin |

| q | 2 x |

| q | Insert in gearbox cover |

| 12 - | Oil drain plug, 40 Nm |

| 13 - | Gearbox housing |

| q | Removing and installing differential → Chapter |

| q | Servicing gearbox housing → Chapter |

| 14 - | Oil filler plug, 40 Nm |

| 15 - | Bolt, 24 Nm |

| q | 2 x |

| q | Apply locking fluid -AMV 185 101 A1- when fitting |

| 16 - | Retaining piece |

| q | For guide sleeve |

| 17 - | Guide sleeve |

| q | With oil seal |

| q | Removing and installing oil seal → Item |

| 18 - | O-ring |

| q | Always renew |

| q | Lubricate with gear oil |

| q | Insert in circumferential groove in gearbox cover |

| 19 - | Circlip |

| q | Insert in circumferential groove in input shaft |

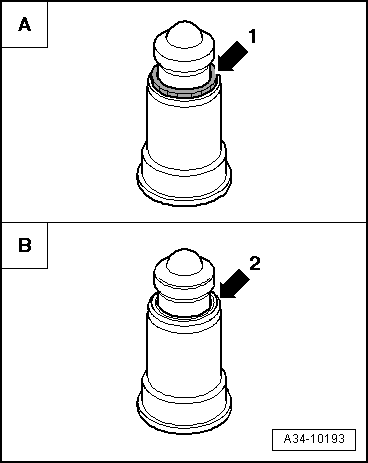

| 20 - | Locking bush |

| q | For selector shaft |

| q | 2 x |

| q | Do not interchange locking bushes for selector shaft and selector rods |

| q | Modification: with flanged edge on ball sleeve → Fig. |

| 21 - | Selector shaft with selector cylinder |

| q | Removing and installing → Chapter |

| 22 - | O-ring |

| q | For selector shaft cover |

| q | Always renew |

| q | Lubricate with gear oil |

| q | Insert in circumferential groove in selector shaft cover |

| 23 - | Bolt, 24 Nm |

| q | 3 x |

| q | Apply locking fluid -AMV 185 101 A1- when fitting |

| 24 - | Cover for selector shaft |

| q | With reversing light switch -F4- |

| q | Removing and installing reversing light switch -F4- → 6-speed manual gearbox 0A3, four-wheel drive; Rep. Gr.34 |

| q | Tightening torque for reversing light switch -F4-, 20 Nm |

| 25 - | Pin |

| q | For selector shaft stop |

| q | Insert in drilling in gearbox housing. |

Note

Note| t | There are two versions of pins: with or without a lug. Please refer to → Electronic parts catalogue “ETKA” for correct version. |

| t | Installation position of pin with lug: insert end with lug into gearbox housing. |

| 26 - | Locking bush |

| q | For 5th and 6th gear selector rod |

| 27 - | Locking bush |

| q | For 3rd and 4th gear selector rod |

| 28 - | Locking bush |

| q | For 1st and 2nd gear selector rod |

| 29 - | Locking bush |

| q | For reverse gear selector rod |

| 30 - | Bolt, 24 Nm |

Note

Note

|

|