| –

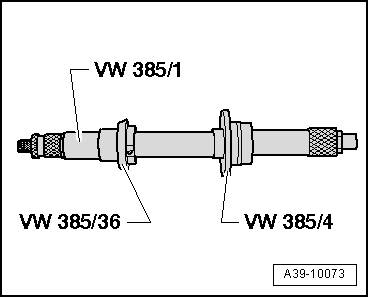

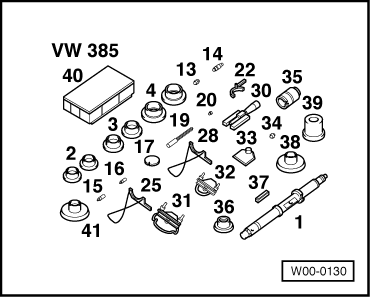

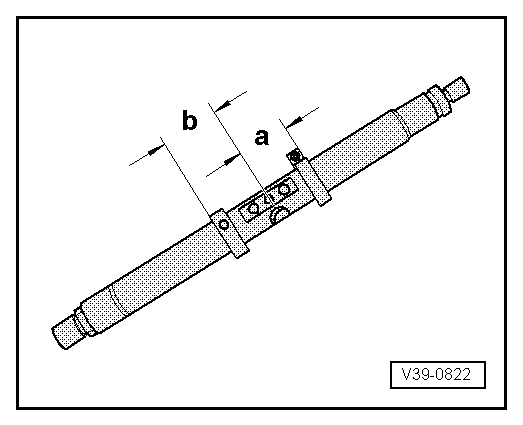

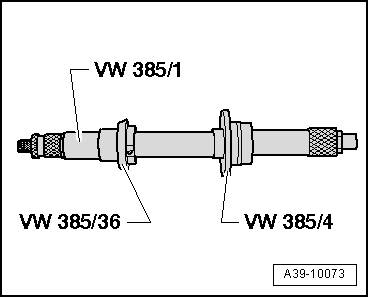

| Assemble universal measuring tool -VW 385/1- as illustrated: |

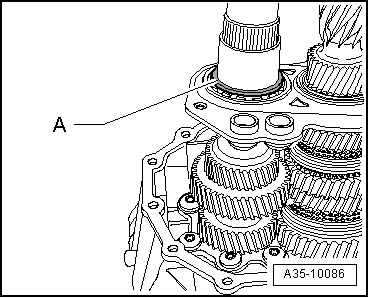

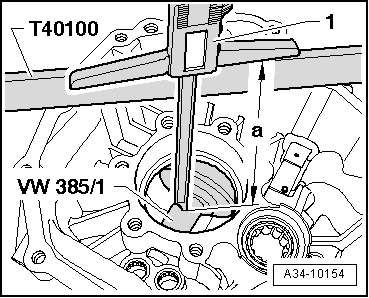

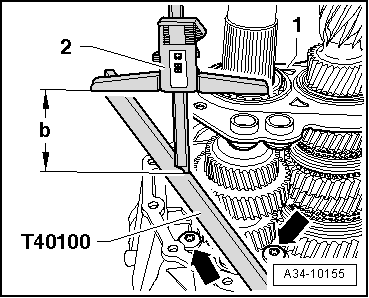

| Determining dimension -A- |

| l

| Tapered roller bearing outer races for differential bearings are installed in gearbox housing and cover for final drive. |

| –

| Insert universal measuring tool -VW 385/1- with centring disc -VW 385/4- facing towards gearbox housing. |

| –

| Fit cover for final drive with O-ring installed and and tighten four bolts to 24 Nm. |

| –

| Using the adjustable ring, move the centring disc outwards until it is no longer possible to turn the universal measuring tool by hand. |

| l

| The round side of universal measuring tool must point up towards depth gauge during this procedure. |

|

|

|

Note

Note