| Checking rectangular section seals for wear |

Note | Always renew rectangular section seals. Nevertheless, the wear pattern on the rectangular section seals gives an indication of the condition of the contact surface for the seals. For this reason it is always advisable to check the rectangular section seals for wear. |

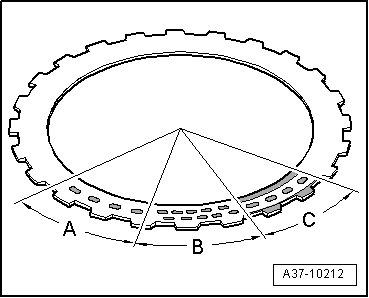

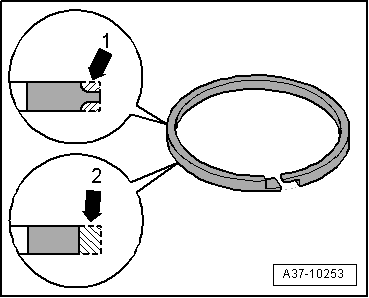

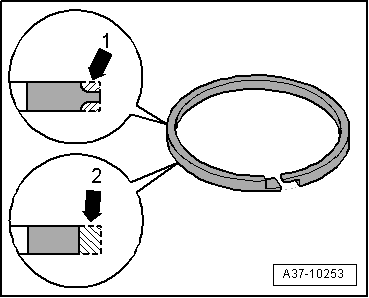

| If the axial wear -arrow 1- on the rectangular section seals is excessive (slight wear on the outside corners is normal): |

| If the radial wear on the rectangular section seals exceeds 0.3 mm -arrow 2- (compare with thickness of new rectangular section seal): |

Note | If the rectangular section seals are worn, the torque converter lock-up clutch may also be worn due to insufficient closing pressure. |

|

|

|

Note

Note Note

Note

Note

Note