A4 Cabriolet Mk2

|

|

|

|

|

|

|

|

|

|

|

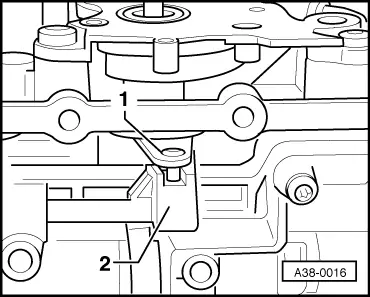

Note

Note

|

|

|

|

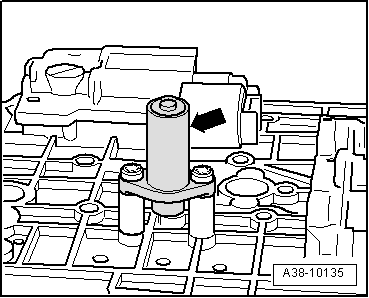

Note

Note

|

|

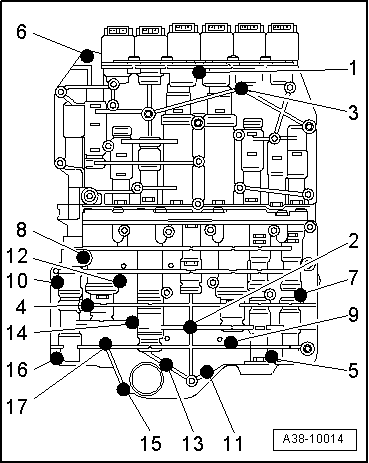

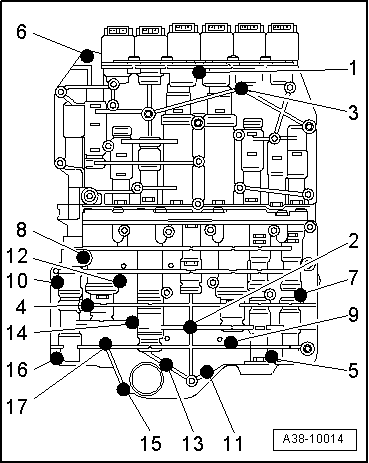

| Step | Tightening sequence | ||

| I |

| ||

| II |

|

|

|

|

|

|

|

|

|

|

|

| Component | Nm |

| Valve body to gearbox housing | 8 |

Caution

Caution