| t

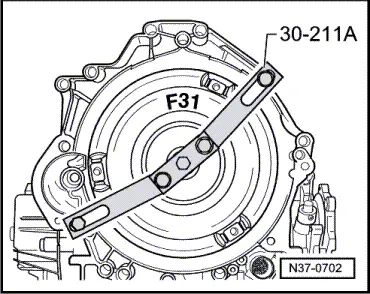

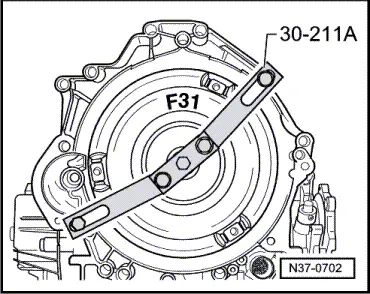

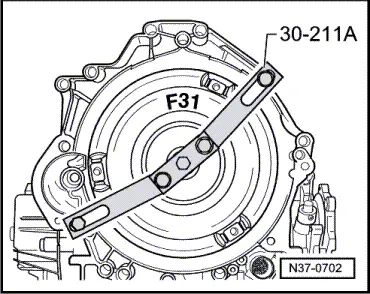

| If gearbox has been removed from vehicle, secure torque converter using support bridge -30-211 A- to prevent it from falling out. |

| t

| Use only ATF or vaseline on all parts running in ATF. Other lubricants will cause malfunction of the gearbox hydraulics. |

| t

| Clean ATF pipes and ATF cooler after performing repairs on the gearbox and renew ATF strainer. |

| Procedure if ATF is dirty |

| If the ATF and related components are very dirty (caused by worn clutch linings): |

| t

| Dismantle complete gearbox and clean all parts, renew ATF pipes. |

| t

| Dismantle and check all clutches. |

| t

| Renew torque converter (cannot be cleaned). |

| t

| Renew valve body (cannot be cleaned). |

| t

| Clean ATF pipes and ATF cooler and renew ATF strainer. |

| O-rings, oil seals and gaskets |

| t

| Always install new O-rings, oil seals and gaskets. |

| t

| After removing gaskets and seals, always inspect the contact surface on the housing or shaft for burrs resulting from removal or for other signs of damage. |

| t

| The open side of the oil seal should face the side containing the fluid. |

| t

| Lightly lubricate the outer circumference and sealing lip of oil seals with ATF before installing. |

| t

| Lightly lubricate O-rings with ATF or vaseline before inserting to prevent them from getting crushed during assembly. |

| t

| Use only ATF or vaseline on all parts running in ATF. Other lubricants will cause malfunction of the gearbox hydraulics. |

| t

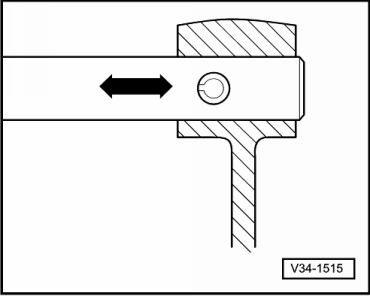

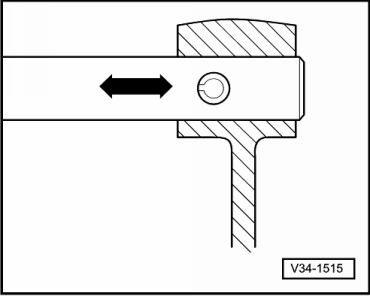

| When installing a new oil seal, position the seal such that the sealing lip does not contact the shaft in the same place as the old seal (make use of installation depth tolerances). |

| t

| Renew paper gaskets, remove previous gaskets completely and clean all sealing surfaces thoroughly. |

| t

| Slacken bolts in reverse sequence to the specified tightening sequence. |

| t

| Nuts and bolts which secure covers and housings should be loosened and tightened in diagonal sequence and in stages if no tightening sequence is specified. |

| t

| The tightening torques stated apply to non-oiled nuts and bolts. |

| t

| Always renew self-locking bolts and nuts. |

|

|

|