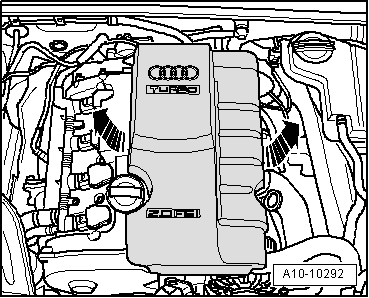

A4 Cabriolet Mk2

|

|

|

|

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

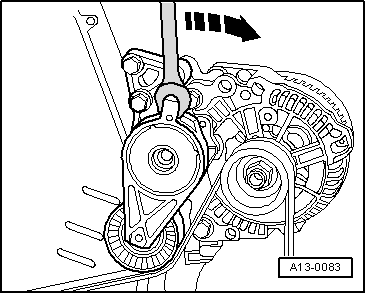

| Component | Nm |

| Tensioning roller to cylinder head | 23 |

| Toothed belt cover (top section) to cylinder head | 10 |

| Tensioner for poly V-belt to bracket for ancillaries | 23 |

Caution

Caution