Note | t

| Renew self-locking nuts and bolts when performing assembly work. |

| t

| Renew bolts which are tightened to a specified angle as well as oil seals, gaskets and O-rings. |

| t

| Hose connections and hoses for charge air system must be free of oil and grease before assembly. |

| t

| Secure all hose connections with the correct type of hose clips (same as original equipment) → Parts catalogue. |

| t

| Fit all cable ties in the original positions when installing. |

| Vehicles with manual gearbox: |

| –

| When fitting a new clutch plate together with a used pressure plate (self-adjusting clutch), the adjuster ring in the pressure plate has to be reset by turning it back as far as it will go. If this is not done, the pressure plate will operate with reduced clamping force, causing clutch slip → Rep. gr.30. |

Note | t

| If the clutch plate is not being replaced, it is not necessary to reset the adjuster ring. |

| t

| New SAC pressure plates are already pre-set accordingly, and do not have to be reset. |

| –

| Clean input shaft splines and (in the case of used clutch plates) the hub splines. Remove corrosion and apply only a very thin coating of grease -G 000 100- to the splines. Do not lubricate guide sleeve. |

| –

| Check that the clutch plate is properly centralised (only necessary if you have carried out other work on the clutch). |

| –

| Check clutch release bearing for wear; renew if necessary. |

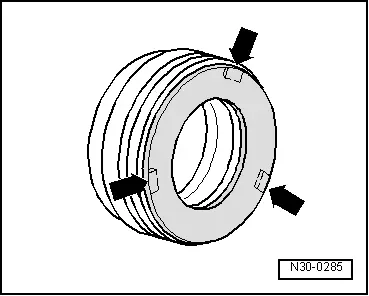

| If the plastic ring for release bearing is loose: |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Caution

Caution