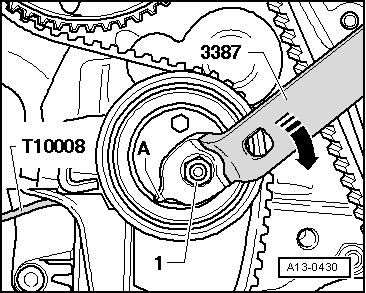

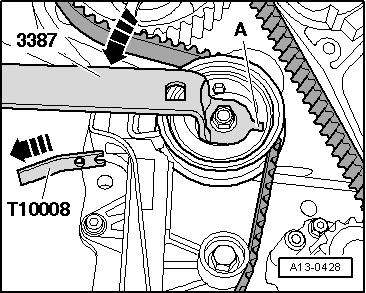

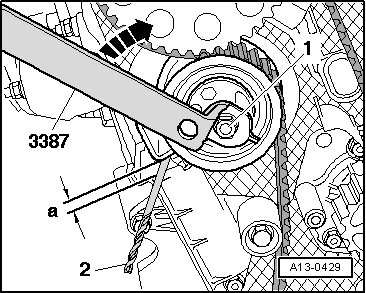

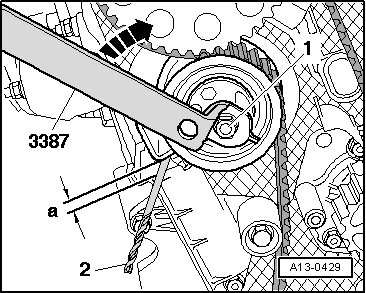

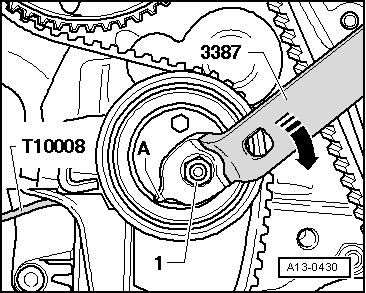

| Do not to bend limit stop -A- of eccentric adjuster. |

| –

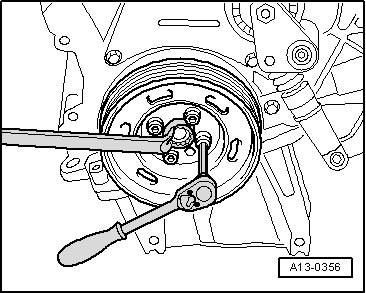

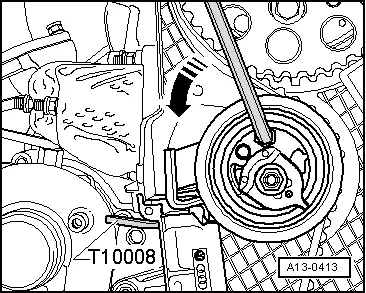

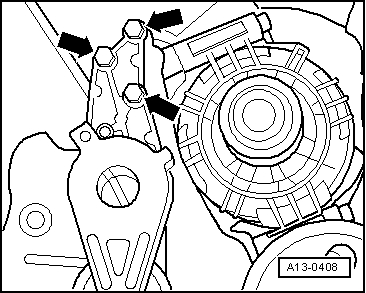

| To slacken toothed belt, loosen nut -1- on tensioning roller and turn eccentric adjuster clockwise -arrow- using pin wrench -3387-. |

| –

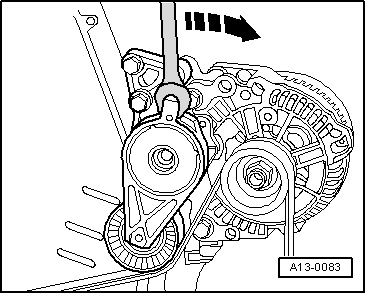

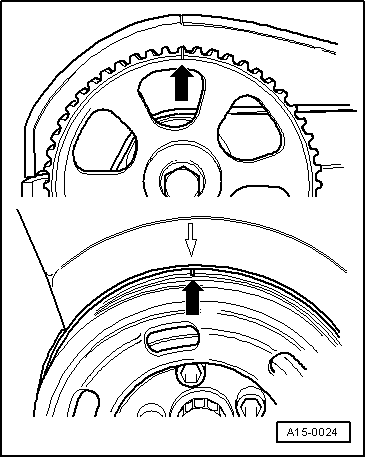

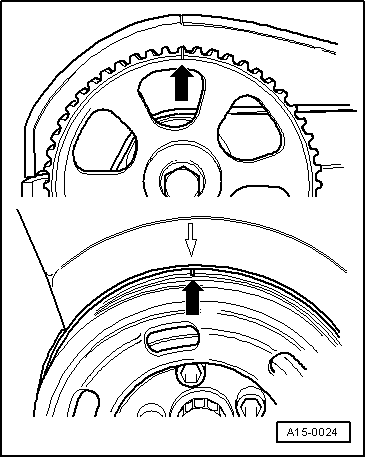

| Mark direction of rotation of toothed belt with chalk or felt pen. |

| Installing (adjusting valve timing) |

Note | t

| The toothed belt adjustment must also be performed as described below, even if the toothed belt has only been removed from the camshaft sprocket. |

| t

| The crankshaft must not be at TDC at any cylinder when the camshaft is turned. Otherwise, there is a risk of damage to valves and piston crowns. |

| –

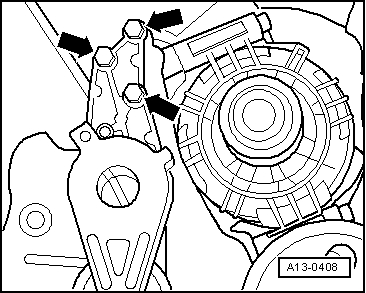

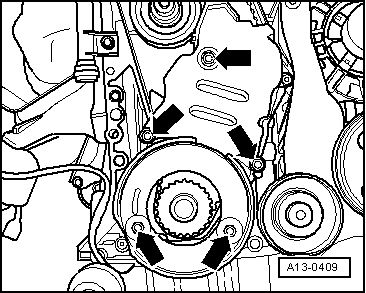

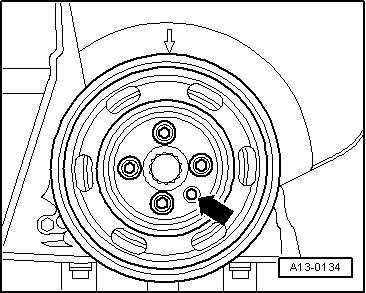

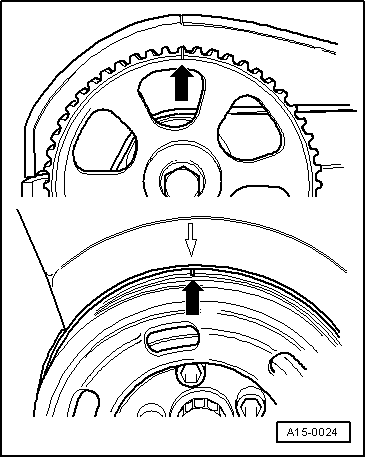

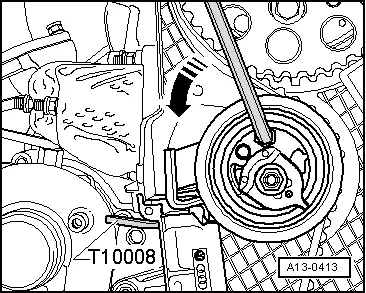

| Fit toothed belt on crankshaft sprocket (note rotation direction). |

| –

| Install bottom toothed belt cover. |

Note |

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution