A4 Cabriolet Mk2

| Renewing crankshaft oil seal (pulley end) |

| Special tools and workshop equipment required |

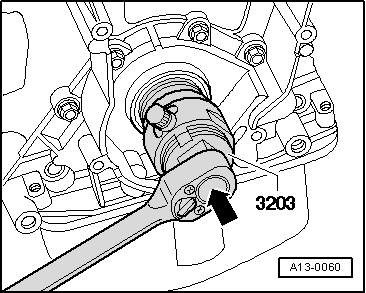

| t | Oil seal extractor -3203- |

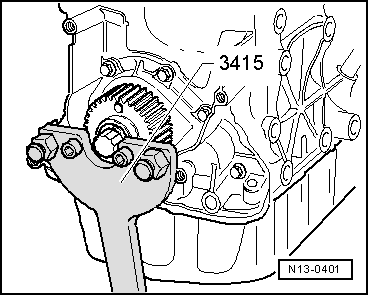

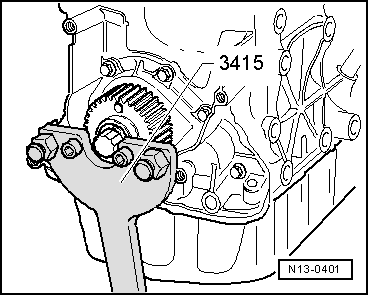

| t | Counterhold tool -3415- |

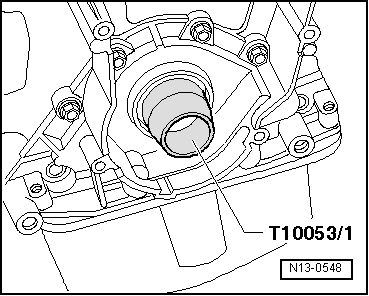

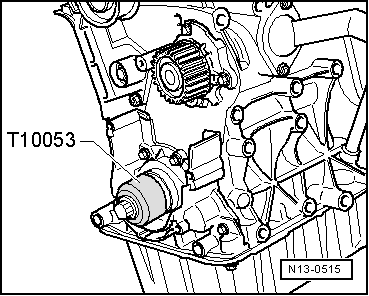

| t | Assembly tool -T10053- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

| Component | Nm |

| Toothed belt sprocket to crankshaft | 90 + 90° → Remark → Remark |

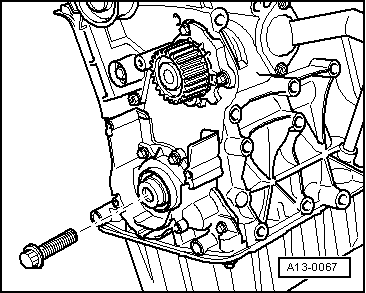

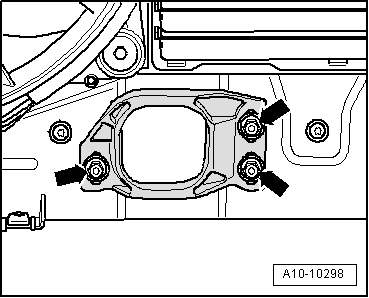

| Stop for torque reaction support to lock carrier | 28 |

|