| –

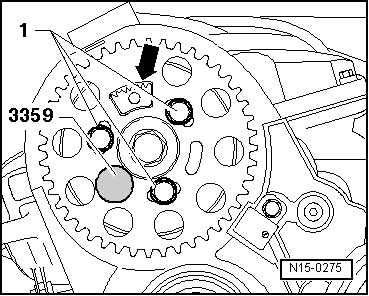

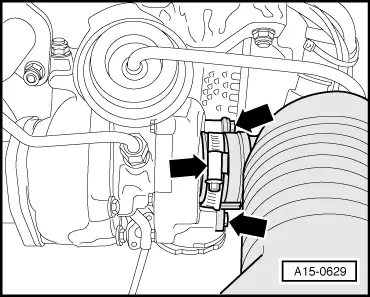

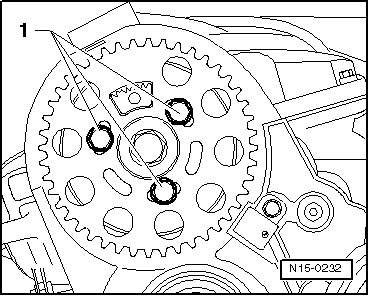

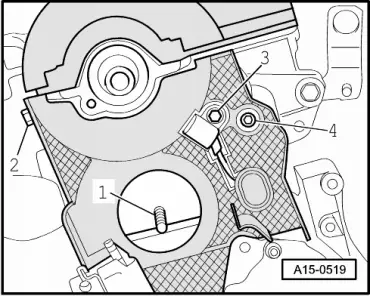

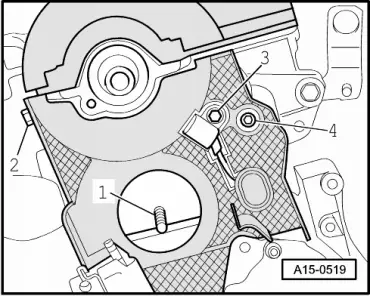

| Push camshaft sprocket onto hub. |

| l

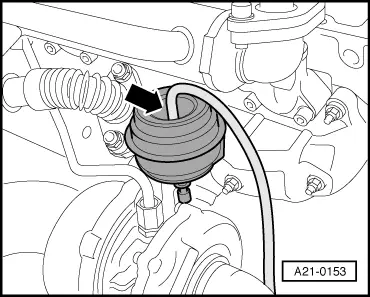

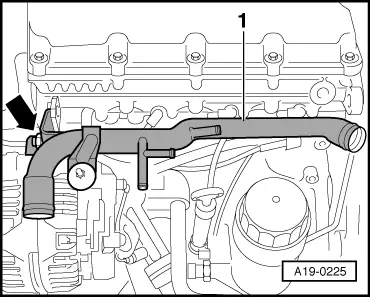

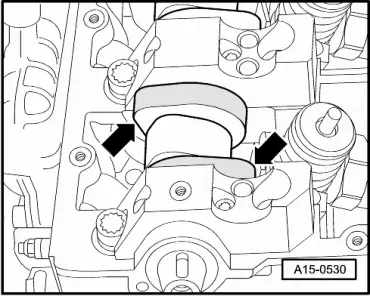

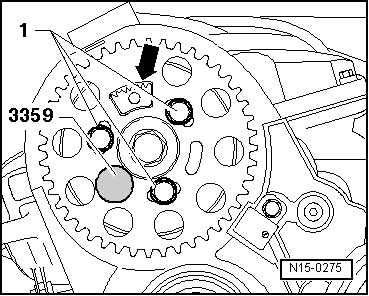

| Toothed segment -arrow- of camshaft sprocket must be at top. |

| –

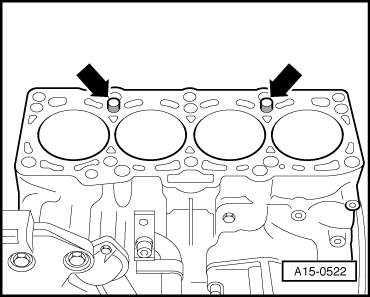

| Screw in bolts -1- finger-tight. |

| –

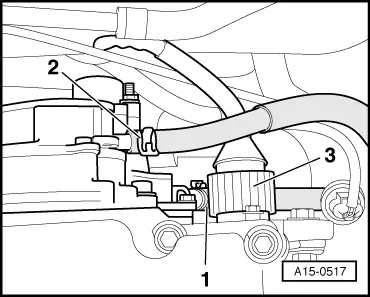

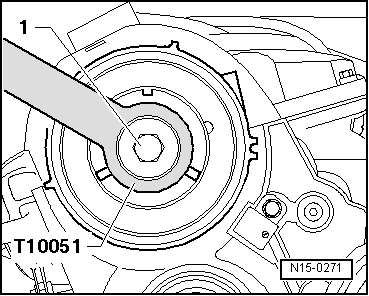

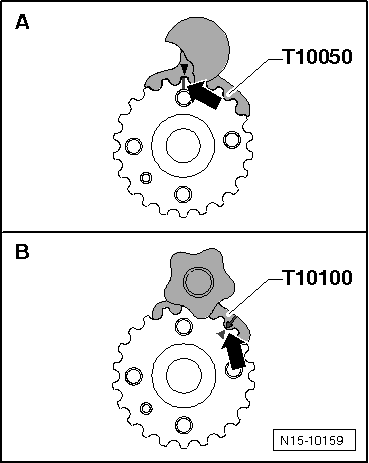

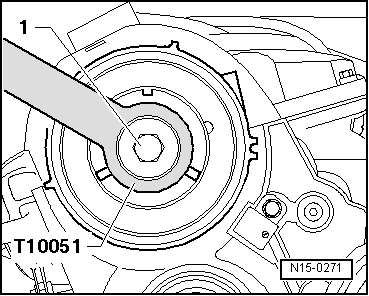

| Lock hub with locking pin -3359-. |

| The remaining installation steps are carried out in the reverse sequence. |

| –

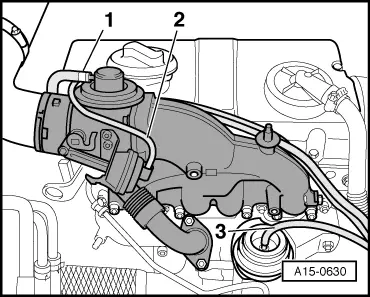

| Fit toothed belt (adjust valve timing): |

| t

| Vehicles with hydraulically damped tensioning roller - engine codes AVB, AVF, AWX → Anchor. |

| t

| Vehicles with friction-damped tensioning roller - engine codes AVB, AVF, AWX → Anchor. |

| t

| Engine codes BKE, BPW, BRB, BRC → Anchor. |

Note | Follow all instructions for removing and installing toothed belt. |

| –

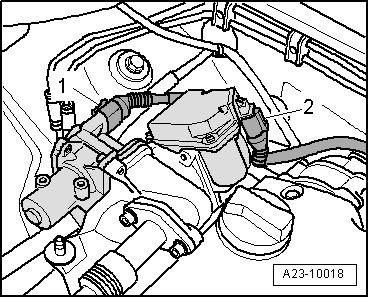

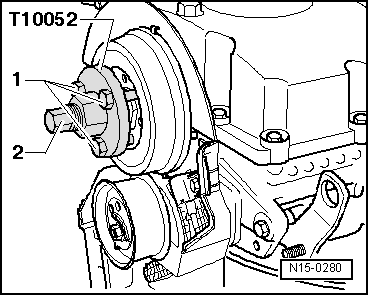

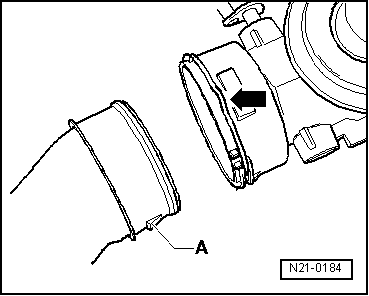

| Install vibration damper: vehicles up to 05.2003 → Anchor, vehicles from 06.2003 onwards → Anchor. |

| –

| Install poly V-belt: vehicles up to 05.2003 → Anchor, vehicles from 06.2003 onwards → Anchor. |

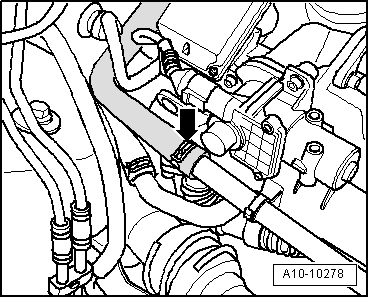

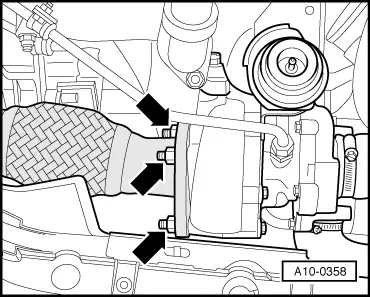

| Vehicles with engine codes AVB, AVF, AWX, BKE: |

| –

| Install catalytic converter together with front exhaust pipe → Chapter. |

| –

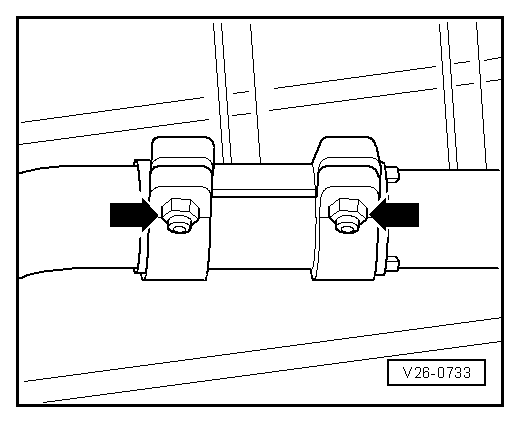

| Align exhaust system so it is free of stress → Chapter. |

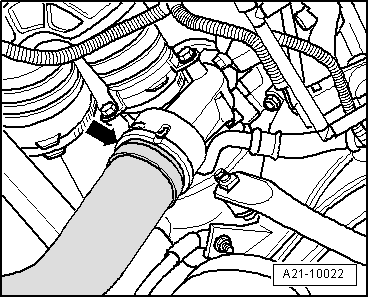

| Vehicles with engine codes BPW, BRB, BRC: |

| –

| Install front exhaust pipe: vehicles with manual gearbox → Chapter; vehicles with multitronic gearbox → Chapter. |

| –

| Align exhaust system so it is free of stress → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution