| –

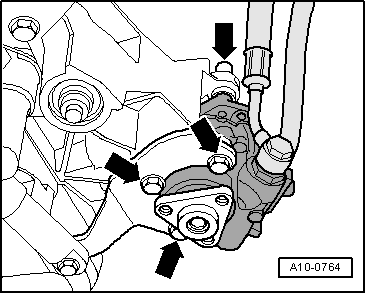

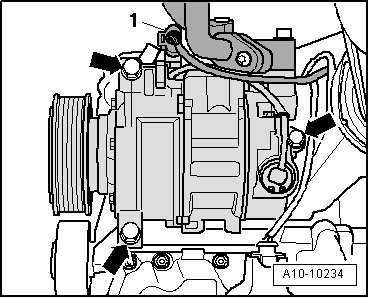

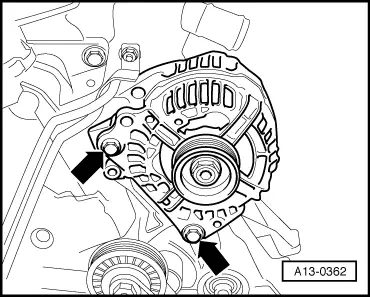

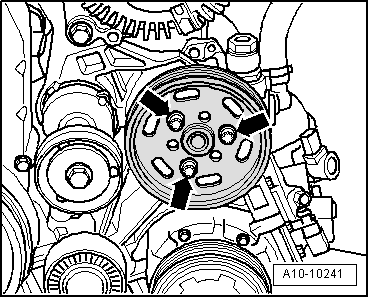

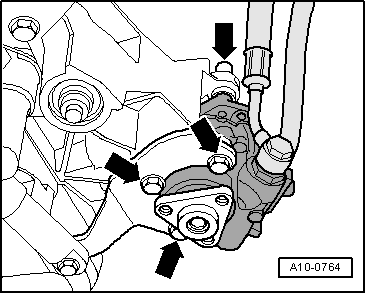

| Unbolt power steering pump -arrows- and tie up to one side; the hoses/pipes remain connected. |

| –

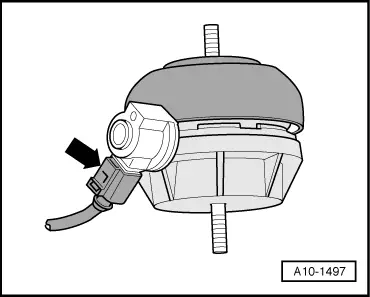

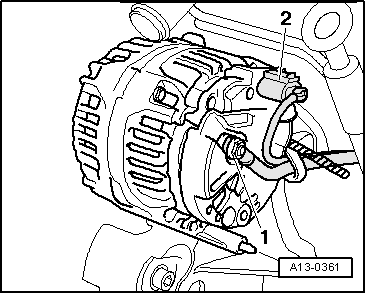

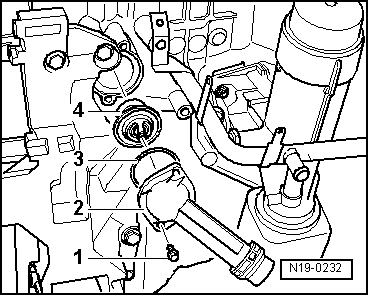

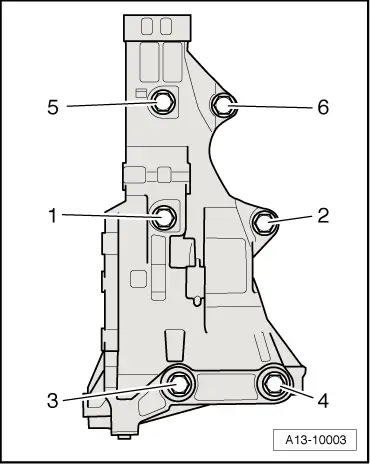

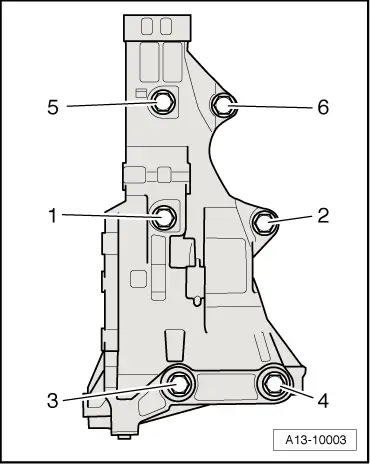

| Take out bracket for ancillaries. |

| –

| If the bracket for ancillaries is renewed, the poly V-belt tensioner must be removed → Chapter. |

| Installation is carried out in the reverse order; note the following: |

Note | t

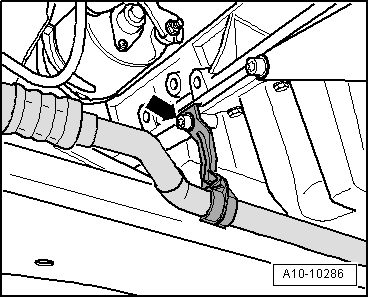

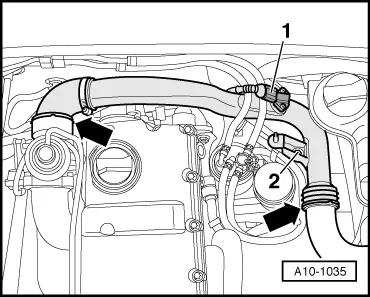

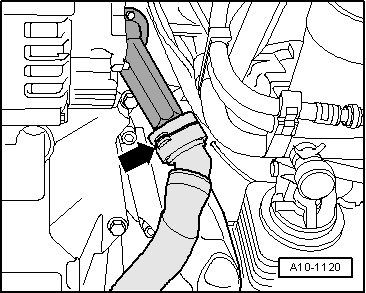

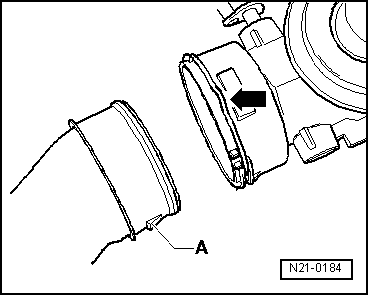

| Hose connections and hoses for charge air system must be free of oil and grease before assembly. |

| t

| To ensure that the charge air hoses can be properly secured at their connections, spray rust remover onto the worm thread of used hose clips before installing. |

| –

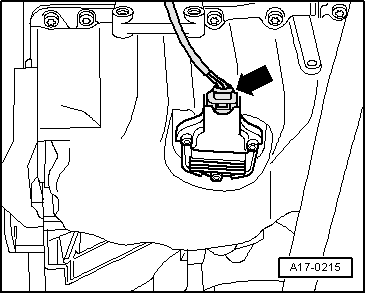

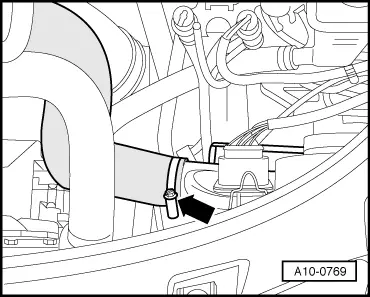

| Check that dowel sleeve at top right between bracket for ancillaries and cylinder block is fitted; insert if necessary. |

| –

| If necessary, install poly V-belt tensioner → Chapter. |

| –

| Bring bracket for ancillaries into installation position and install power steering pump → Rep. Gr.48. |

|

|

|

Note

Note

Note

Note

Caution

Caution WARNING

WARNING