A4 Cabriolet Mk2

| Removing and installing toothed belt |

| Special tools and workshop equipment required |

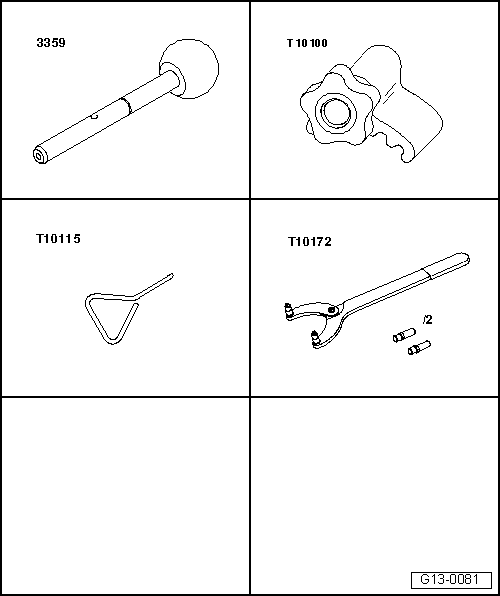

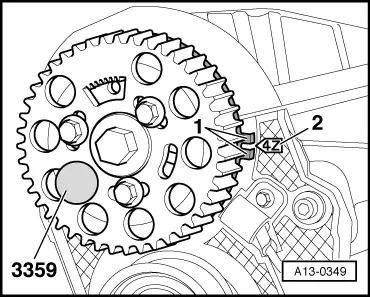

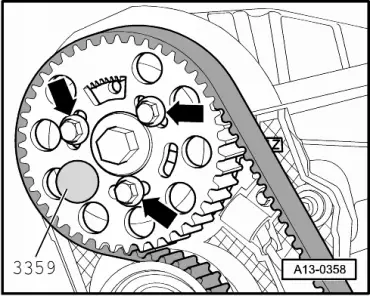

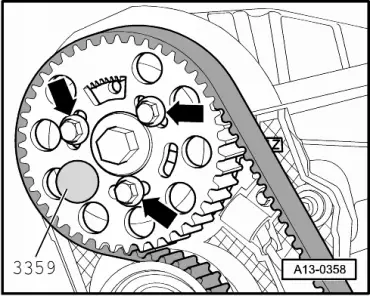

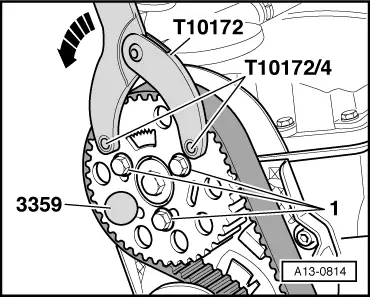

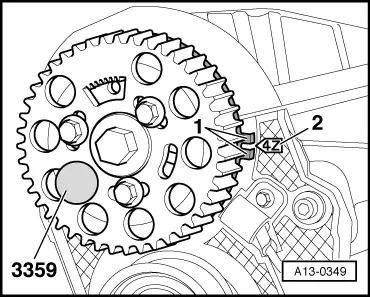

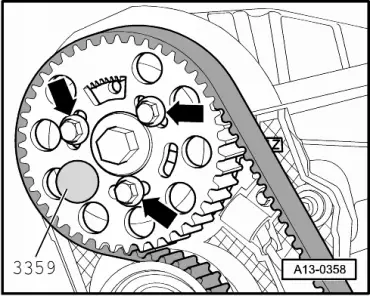

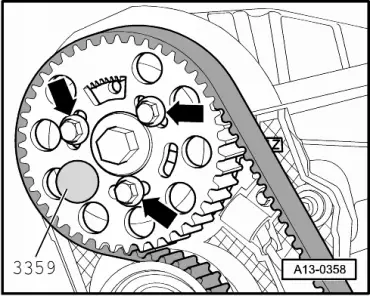

| t | Diesel injection pump locking pin -3359- |

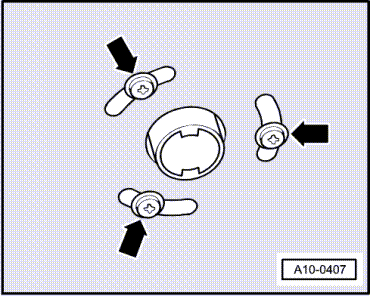

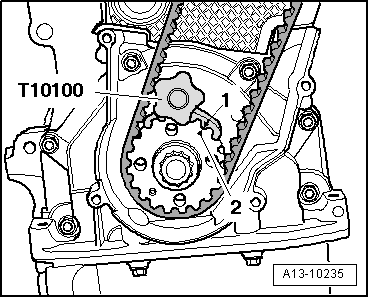

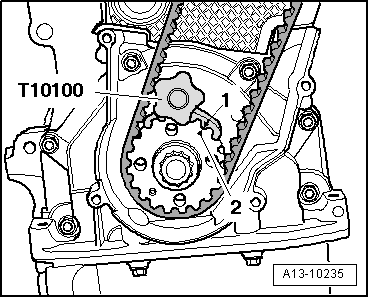

| t | Crankshaft stop -T10100- |

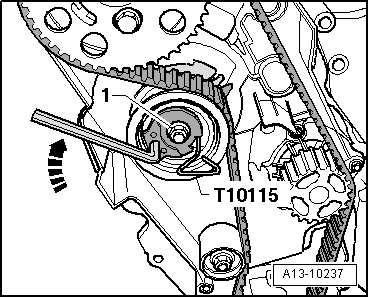

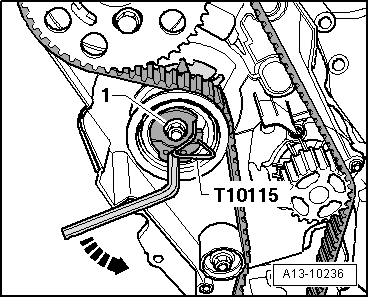

| t | Locking pin -T10115- |

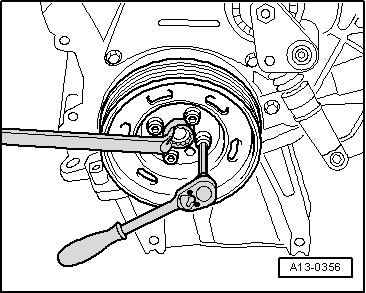

| t | Counterhold tool -T10172- with pin -T10172/4- |

| t | Locking fluid → Electronic parts catalogue |

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

| Component | Nm | ||

| Camshaft sprocket to hub | 25 | ||

| Tensioning roller for toothed belt to cylinder head | 20 + 45° | ||

| Toothed belt cover (bottom) to cylinder block | 10 1) | ||

| Toothed belt cover (centre) to cylinder block | 10 1) | ||

| |||

Caution

Caution