A4 Cabriolet Mk2

| Removing engine |

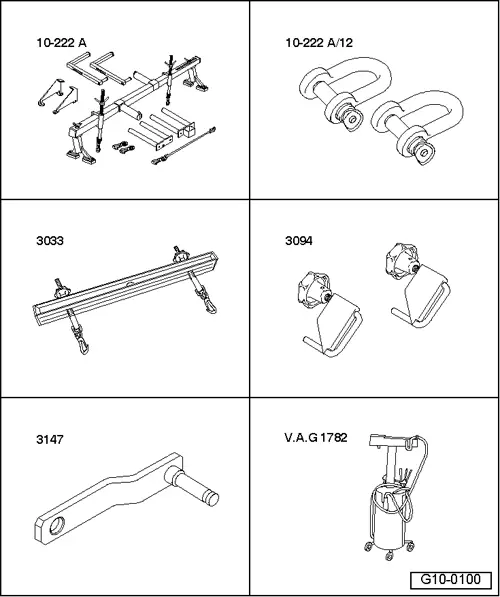

| Special tools and workshop equipment required |

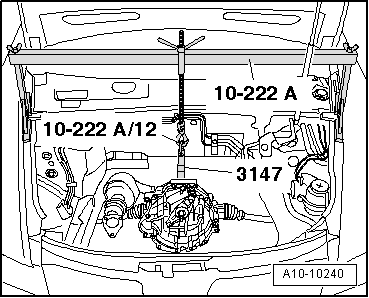

| t | Support bracket -10-222 A- |

| t | Shackle -10-222 A/12- |

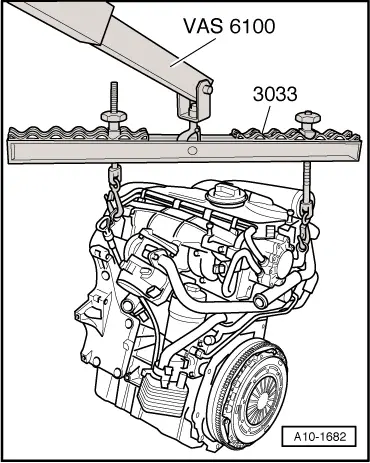

| t | Lifting tackle -3033- |

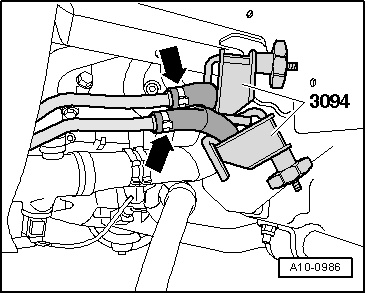

| t | Hose clamps for hoses up to 25 mm Ø -3094- |

| t | Gearbox support -3147- |

| t | Used oil collection and extraction unit -V.A.G 1782- |

| t | Hose clip pliers -V.A.G 1921- |

| t | Workshop hoist -VAS 6100- |

| t | Drip tray for workshop hoist -VAS 6208- |

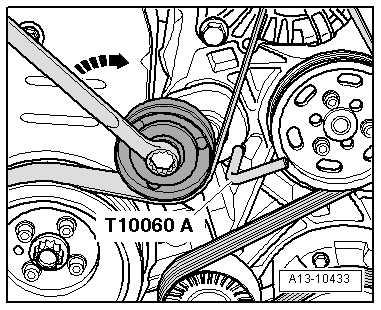

| t | Locking pin -T10060 A- |

| t | Safety goggles |

| t | Protective gloves |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Caution

Caution WARNING

WARNING