A4 Cabriolet Mk2

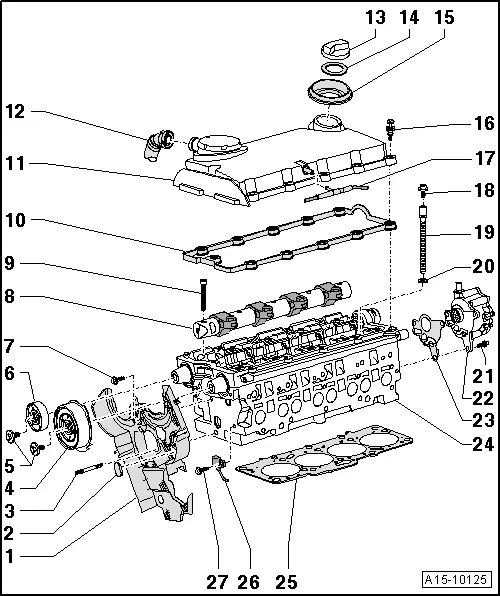

| Cylinder head - exploded view |

| 1 - | Toothed belt cover (rear) |

| 2 - | Rubber grommet |

| q | Renew if damaged |

| 3 - | Threaded pin, 15 Nm |

| 4 - | Hub for inlet camshaft |

| q | With sender wheel for Hall sender -G40- |

| q | To remove, use puller -T10052- → Anchor |

| 5 - | 100 Nm |

| q | Use counterhold tool -T10051- when loosening and tightening → Chapter „Removing and installing camshafts“ |

| 6 - | Hub for exhaust camshaft |

| q | Different types depending on production version |

| q | To remove, use puller -T10052- → Anchor |

| 7 - | 10 Nm |

| q | Apply locking fluid when installing; refer to → Electronic parts catalogue |

| 8 - | Rocker arm shaft |

| q | Mark allocation of rocker arms |

| q | Do not interchange |

| q | Removing and installing → Chapter „Removing and installing cylinder head“ |

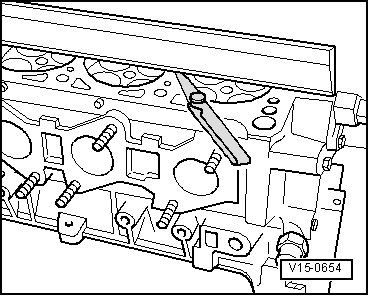

| q | Before installing, check that all ball studs and O-rings are inserted in the unit injectors → Fig. |

| 9 - | Bolt for rocker arm shaft |

| q | Renew |

| q | Note correct sequence when loosening → Anchor |

| q | Note correct sequence when tightening → Anchor |

| 10 - | Gasket for cylinder head cover |

| q | Renew if damaged or leaking |

| q | Engage in spacer sleeves of → Item |

| 11 - | Cylinder head cover |

| q | Removing and installing → Chapter |

| 12 - | Crankcase breather hose |

| 13 - | Filler cap |

| 14 - | Seal |

| q | Renew if damaged or leaking |

| 15 - | Cap |

| 16 - | Special bolt, 10 Nm |

| q | Renew if damaged or leaking |

| q | Note sequence for loosening and tightening → Chapter „Removing and installing cylinder head cover“ |

| 17 - | Vacuum hose |

| 18 - | 20 Nm |

| 19 - | Cylinder head bolt |

| q | Renew |

| q | Note correct sequence when loosening → Anchor |

| q | Note correct sequence when tightening → Anchor |

| 20 - | Washer |

| q | When cylinder head is removed, fit washer in cylinder head before installing bearing frame |

| 21 - | 20 Nm |

| 22 - | Tandem pump |

| q | Removing and installing → Rep. Gr.20 |

| 23 - | Gasket |

| q | Renew |

| 24 - | Cylinder head |

| q | Removing and installing → Chapter |

Caution

Caution

|

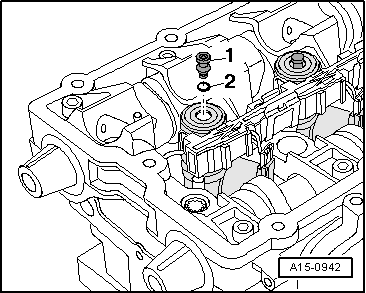

| q | Checking for distortion → Fig. |

| q | If renewed, change coolant and engine oil |

| 25 - | Cylinder head gasket |

| q | Renewing → Chapter „Removing and installing cylinder head“ |

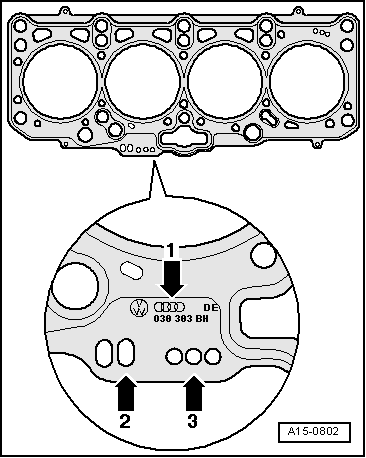

| q | Note marking → Fig. |

| q | If renewed, change coolant and engine oil |

| 26 - | Hall sender -G40- |

| q | For camshaft position |

| 27 - | 10 Nm |

| q | Apply locking fluid when installing; refer to → Electronic parts catalogue |

|

|

Note

Note

|

|