A4 Cabriolet Mk2

| Removing and installing sump |

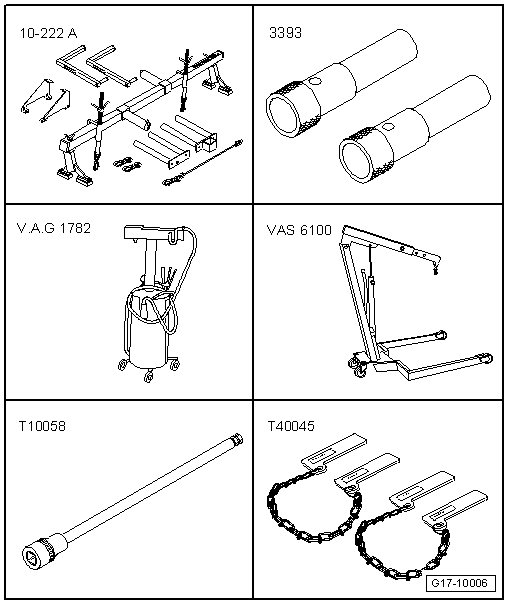

| Special tools and workshop equipment required |

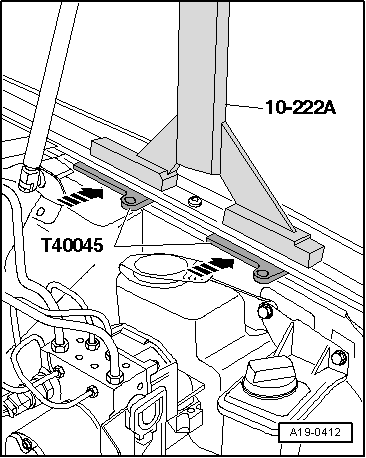

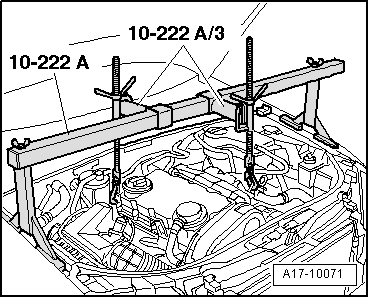

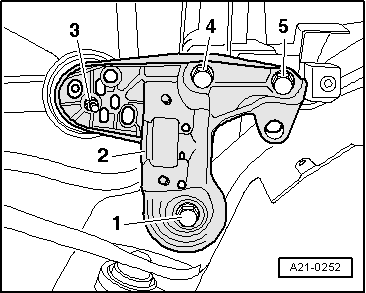

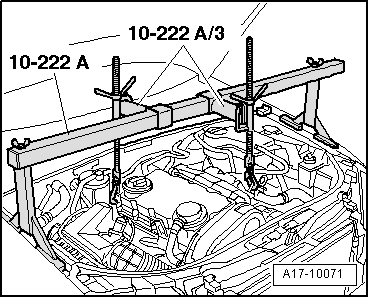

| t | Support bracket -10-222 A- |

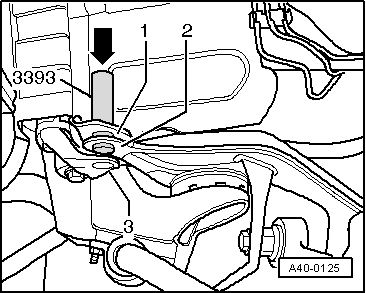

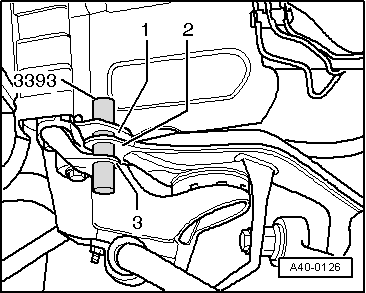

| t | Locating pins -3393- |

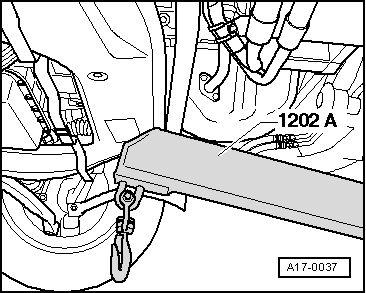

| t | Used oil collection and extraction unit -V.A.G 1782- |

| t | Workshop hoist -VAS 6100- |

| t | Allen key (long reach) -T10058- |

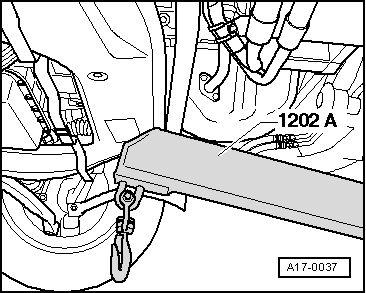

| t | Mud wing compensation plate -T40045- |

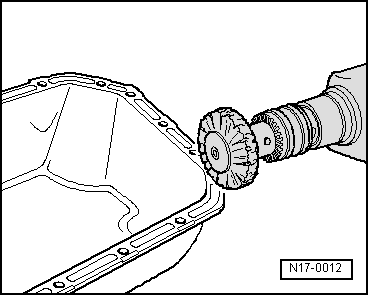

| t | Electric drill with plastic brush attachment |

| t | Safety goggles |

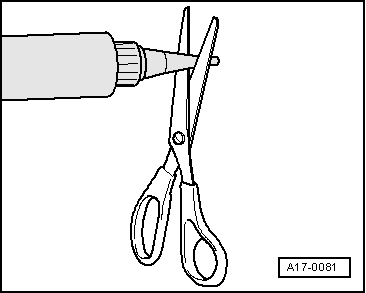

| t | Sealant → Electronic parts catalogue |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

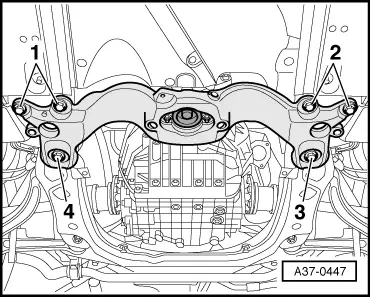

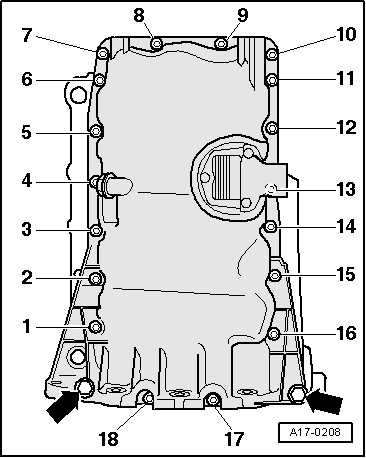

| Component | Nm | |

| Oil drain plug | 30 | |

| Sump to: | M7 | 15 |

| Cylinder block | M10 | 40 |

| Sump to gearbox | 45 | |

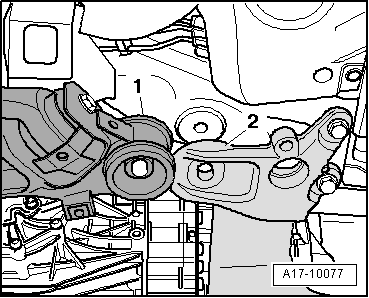

| Torque reaction support to sump | 23 | |

| Engine mounting to console for engine mounting | 40 | |

| Console for engine mounting to longitudinal member | 75 | |

Caution

Caution WARNING

WARNING