A4 Cabriolet Mk2

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

|

|

|

|

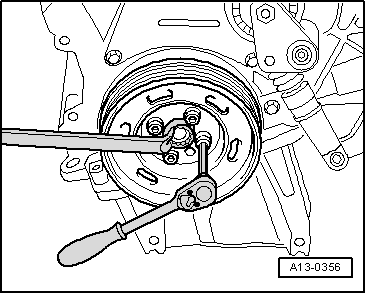

| Component | Nm | ||||

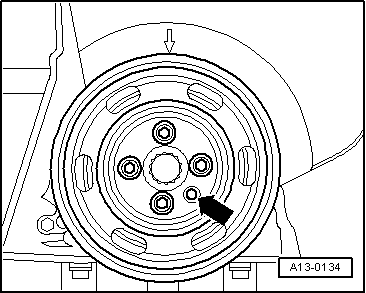

| Vibration damper to crankshaft | 10 + 90° 1)2) | ||||

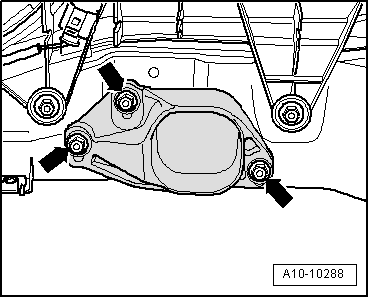

| Stop for torque reaction support to lock carrier | 28 | ||||

| Hose clips (9 mm wide) | 3 | ||||

| Hose clips (13 mm wide) | 5.5 | ||||

| |||||