A4 Cabriolet Mk2

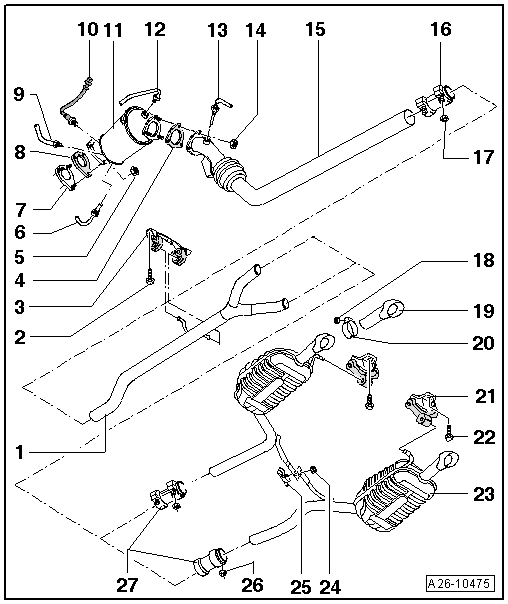

| Exhaust system on vehicles with four-wheel drive - exploded view |

| 1 - | Y-pipe |

| q | Combined in one unit with rear silencers as original equipment. Can be renewed individually for repair purposes |

| q | Cutting point → Anchor |

| q | Align exhaust system so it is free of stress → Chapter |

| 2 - | 25 Nm |

| 3 - | Mounting |

| q | Renew if damaged |

| 4 - | Gasket |

| q | Renew |

| 5 - | 27 Nm |

| q | Renew |

| q | Coat with high-temperature paste; for high-temperature paste refer to → Electronic parts catalogue |

| 6 - | Temperature sender before particulate filter -G506- |

| q | Tighten to 45 Nm |

| q | Removing and installing → Chapter |

| 7 - | Turbocharger |

| 8 - | Gasket |

| q | Renew |

| 9 - | Pressure line |

| q | Tighten union nuts to 30 Nm. |

| 10 - | Lambda probe -G39- |

| q | Threads of new Lambda probes are already greased with assembly paste; the paste must not get into the slots on the probe body |

| q | When re-using the old Lambda probe, grease thread with high-temperature paste lubricant; the paste must not get into the slots of the probe body. High-temperature paste → Electronic parts catalogue |

| q | Remove and install using ring spanner for Lambda probe -3337- → Rep. Gr.23 |

| q | Tighten to 55 Nm |

| 11 - | Particulate filter |

| q | Removing and installing → Chapter |

| q | Protect against knocks and impact |

| q | After renewing particulate filter perform adaption in “Guided Fault Finding” mode → Vehicle diagnosis, testing and information system VAS 5051 |

| 12 - | Pressure line |

| q | Tighten union nuts to 30 Nm. |

| 13 - | Temperature sender after particulate filter -G527- |

| q | Tighten to 45 Nm |

| q | Removing and installing → Chapter |

| 14 - | 23 Nm |

| q | Renew |

| q | Coat with high-temperature paste; for high-temperature paste refer to → Electronic parts catalogue |

| 15 - | Front exhaust pipe |

| q | With flexible joint |

| q | Do not bend flexible joint more than 10° – otherwise it can be damaged |

| q | Removing and installing → Chapter |

| q | Mounting components → Chapter |

| q | Align exhaust system so it is free of stress → Chapter |

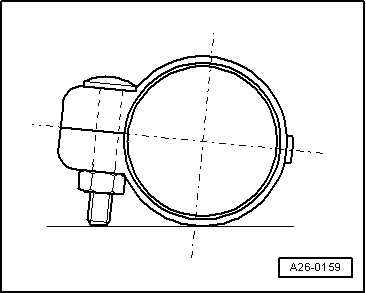

| 16 - | Clamp (front) |

| q | Installation position → Fig. |

| q | Before tightening, align exhaust system so it is free of stress → Chapter |

| q | Tighten bolt connections evenly |

| 17 - | 23 Nm |

| 18 - | 25 Nm |

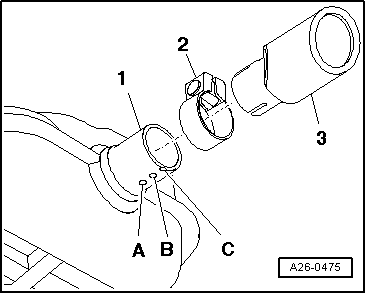

| 19 - | Tailpipe |

| q | Renewing → Fig. |

| 20 - | Clip |

| 21 - | Mounting |

| q | Renew if damaged |

| q | Check preload → Chapter „Stress-free alignment of exhaust system“ |

| 22 - | 23 Nm |

| 23 - | Rear silencer |

| q | Combined in one unit with centre silencer as original equipment. Can be renewed individually for repair purposes |

| q | Cutting point → Anchor |

| q | Align exhaust system so it is free of stress → Chapter |

| 24 - | 23 Nm |

| 25 - | Connecting bracket |

| 26 - | 23 Nm |

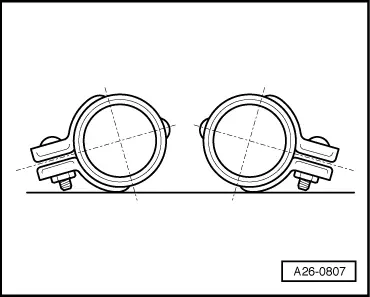

| 27 - | Clamp (rear) |

| q | For separate replacement of centre and rear silencers |

| q | Before tightening, align exhaust system so it is free of stress → Chapter |

| q | Installation position → Fig. |

| q | Tighten bolt connections evenly |

|

|

|

|

Note

Note