A4 Cabriolet Mk2

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

| Component | Nm | |

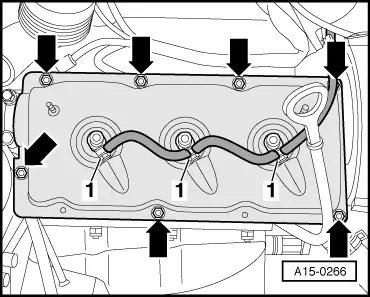

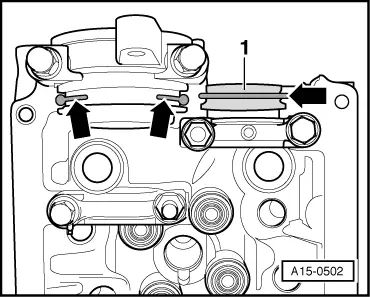

| Cylinder head cover to cylinder head | 10 → Note | |

| Guide tube for dipstick to cylinder head | 10 | |

| Return pipes to injectors | 5 | |

| Injector pipes to: | Injectors | 30 |

| Injection pump | 30 | |

|