| –

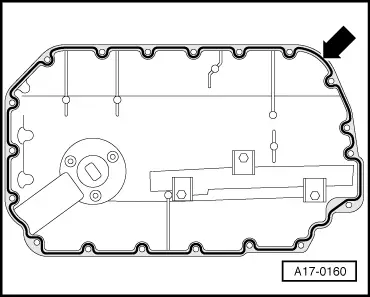

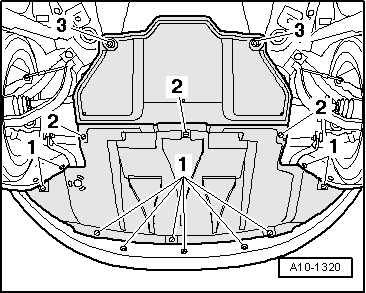

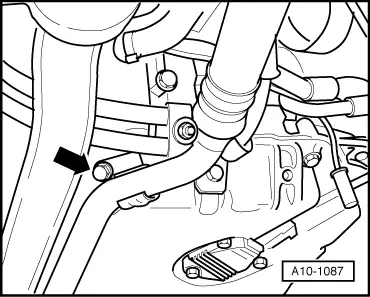

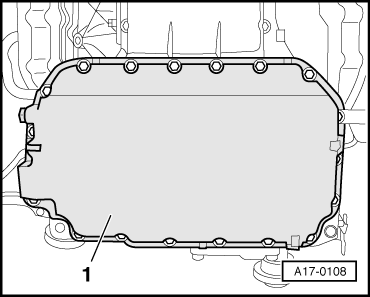

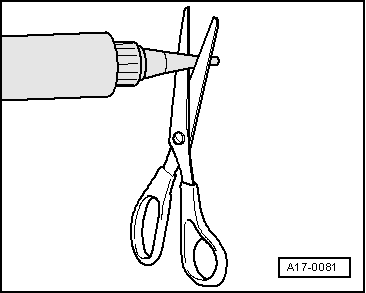

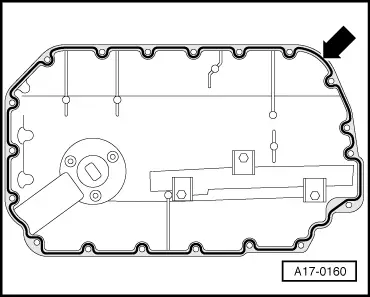

| Apply the bead of sealant onto the clean sealing surface of the sump (bottom section) as illustrated. |

| l

| Width of sealant bead -arrow-: 2 ... 3 mm. |

Note | Sealant bead must not be wider than 3 mm, otherwise excess sealant could ingress into sump and clog strainer in oil intake pipe. |

| –

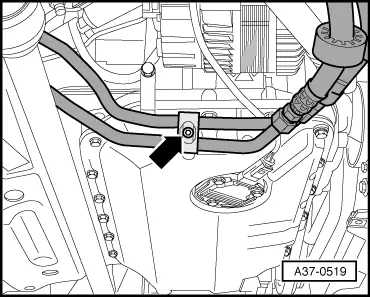

| Fit sump (bottom section) and tighten all bolts initially to 5 Nm in diagonal sequence. |

| –

| Tighten bolts securing sump (bottom section) to 10 Nm in diagonal sequence. |

| –

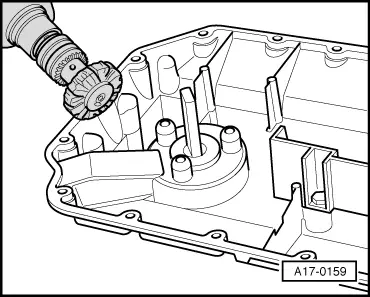

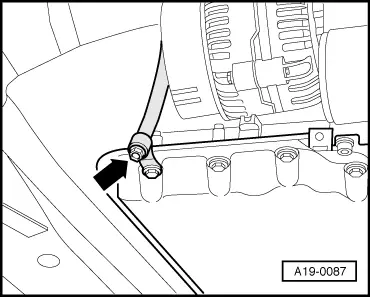

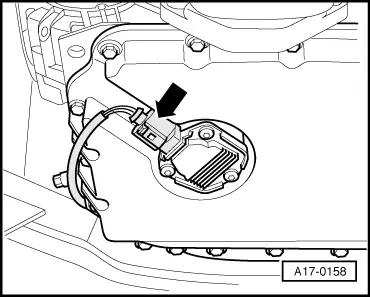

| Fit new O-ring and locate coolant drain pipe carefully on cylinder block and press it as far as it will go into drilling using a lever. |

| –

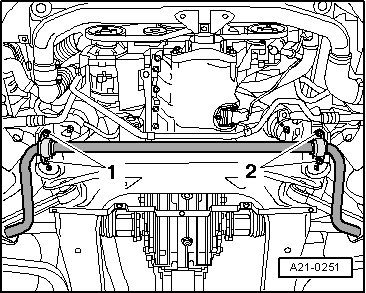

| Fill up with engine oil and check oil level → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING