| –

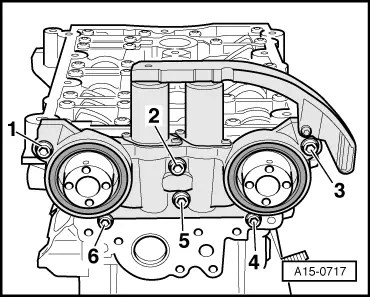

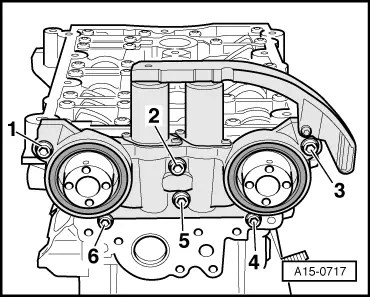

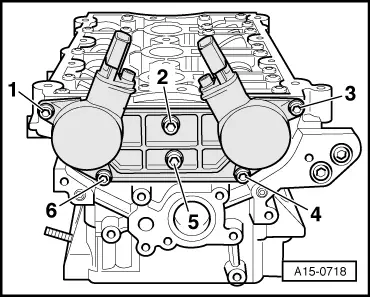

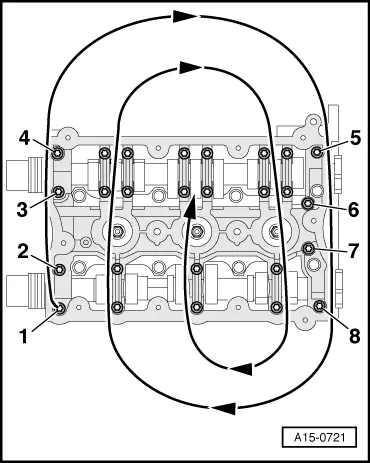

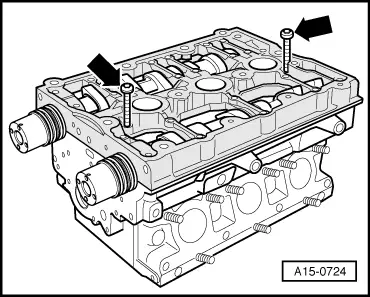

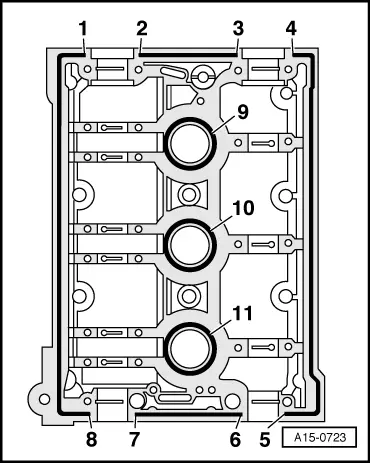

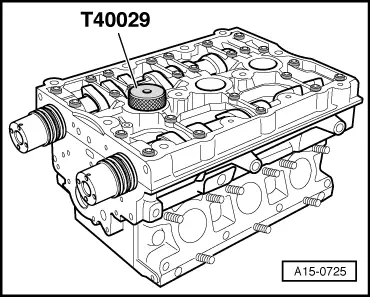

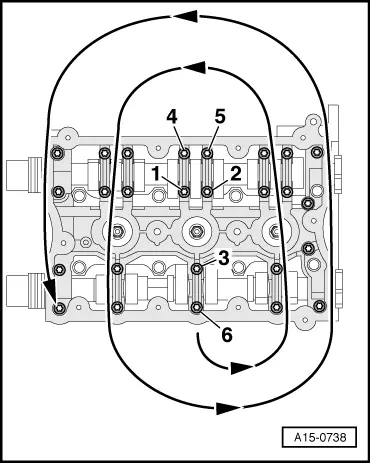

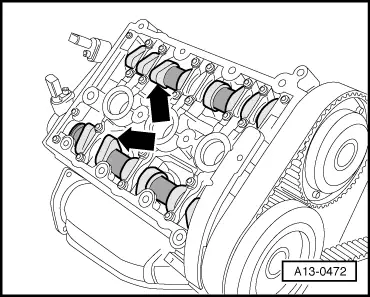

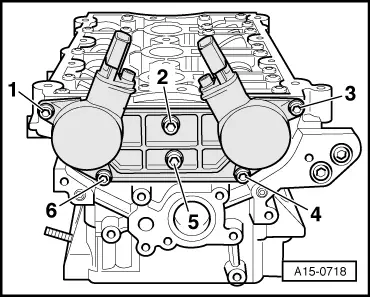

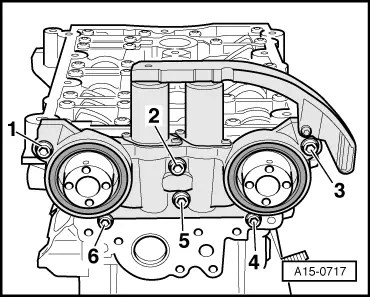

| Install housing for camshaft control valves and tighten bolts -1 ... 6-. |

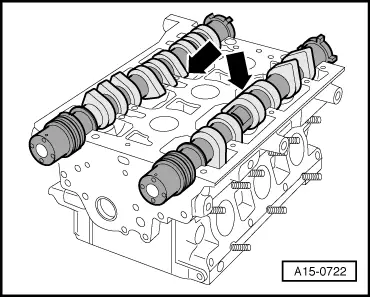

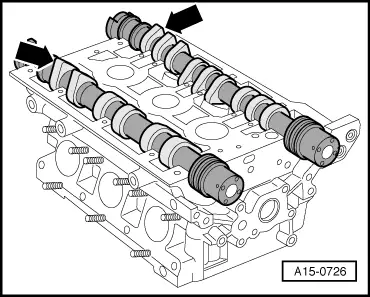

| Remaining installation steps are carried out in reverse sequence; note the following: |

| –

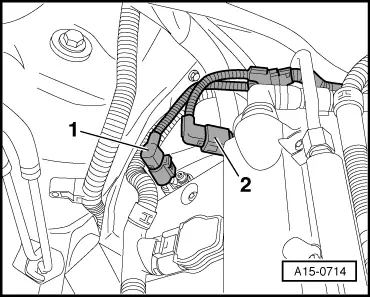

| Install combination valve for secondary air system: left-side → Chapter, right-side → Chapter. |

| –

| Install toothed belt (adjust valve timing) → Anchor. |

Note | t

| After installing camshafts, wait for approx. 30 minutes before starting engine. Hydraulic valve compensation elements have to settle (otherwise valves will strike pistons). |

| t

| After working on the valve gear, turn the engine carefully at least 2 rotations by hand to ensure that none of the valves make contact when the starter is operated. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING