A4 Cabriolet Mk2

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

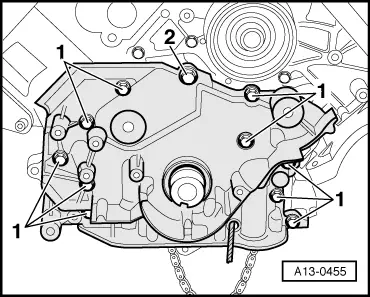

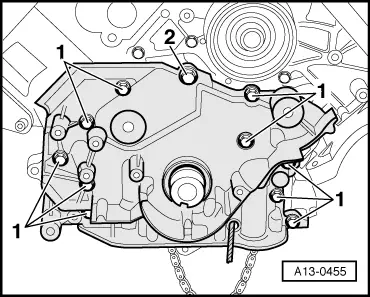

| Component | Nm | |||||

| Front sealing flange to cylinder block | M6 | 10 | ||||

| M8 | 30 1) | |||||

| Tensioning lever to sealing flange (front) | 45 1) | |||||

| Tensioner to sealing flange (front) | 10 | |||||

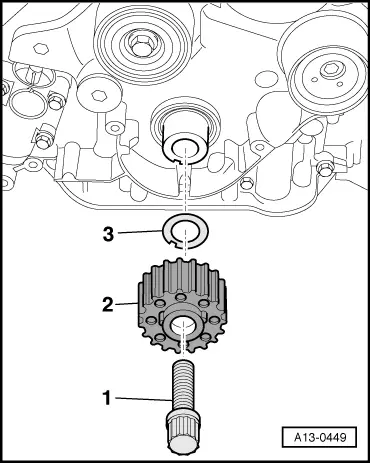

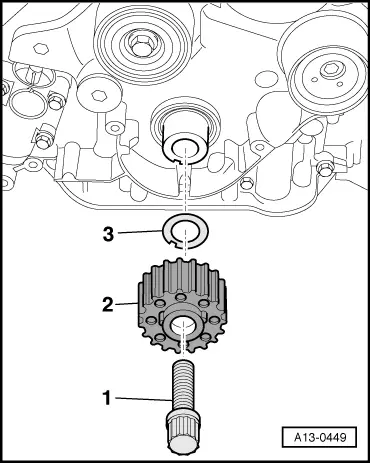

| Toothed belt sprocket to crankshaft | 200 + 180° 1)2) | |||||

| Sealing plug for access hole to sealing flange (front) | 10 | |||||

| ||||||