A4 Cabriolet Mk2

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

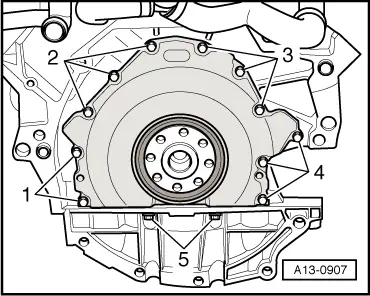

| Component | Nm | |

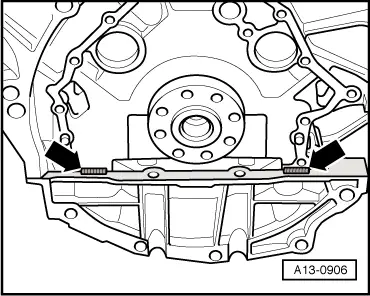

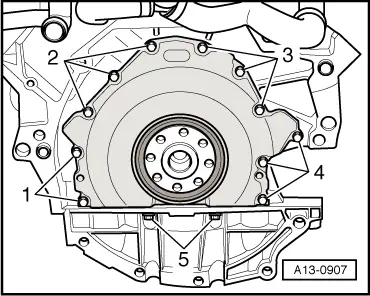

| Rear sealing flange to: | Cylinder block | 10 |

| Sump (top section) | 14 | |

WARNING

WARNING