A4 Cabriolet Mk2

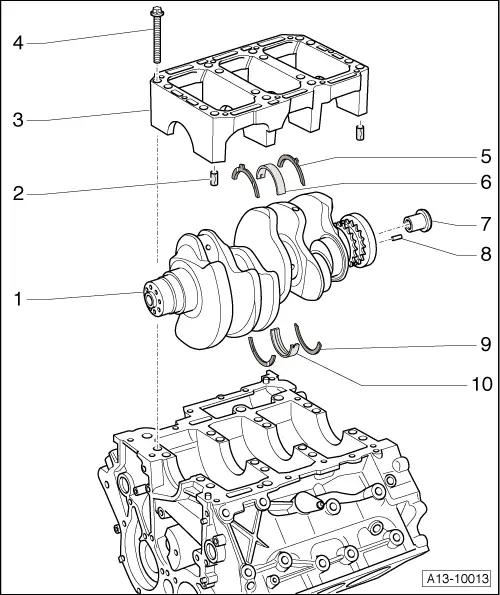

| Crankshaft - exploded view |

| 1 - | Crankshaft |

| q | Measuring axial clearance → Chapter |

| q | Measuring radial clearance → Chapter |

| q | Crankshaft dimensions → Chapter |

| 2 - | Dowel sleeve |

| q | 2x |

| q | Insert in cylinder block |

| 3 - | Retaining frame |

| q | Installing → Fig. |

| 4 - | Bolt |

| q | Renew |

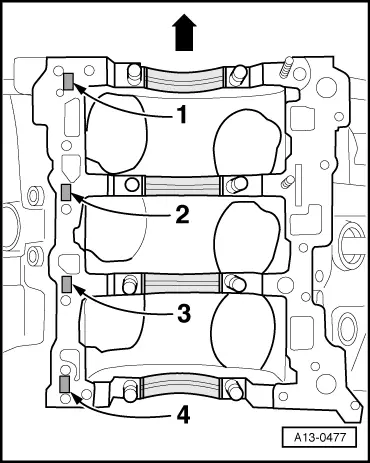

| q | Tightening sequence → Fig. |

| 5 - | Thrust washer |

| q | Only fitted on 3rd crankshaft bearing |

| q | Oil groove faces outwards |

| q | Note location |

| q | Measuring axial clearance of crankshaft → Chapter |

| 6 - | Bearing shell |

| q | For retaining frame |

| q | Renew used bearing shells |

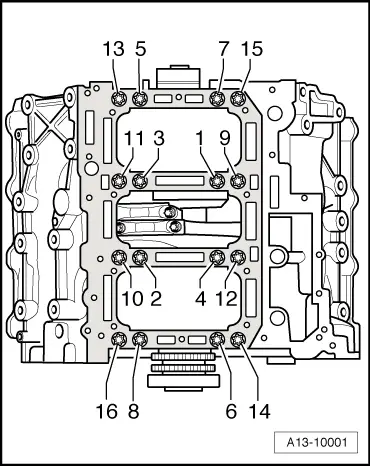

| q | Install new bearing shells for retaining frame with correct coloured markings → Fig. |

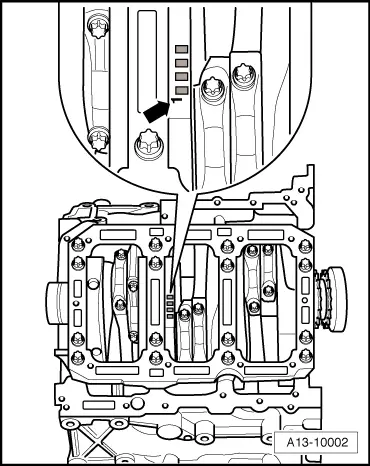

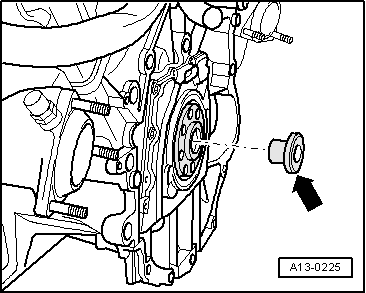

| 7 - | Centring sleeve for torque converter |

| q | For vehicles with automatic gearbox → Fig. |

| 8 - | Dowel pin |

| q | Check that pin is firmly seated in crankshaft |

| 9 - | Thrust washer |

| q | Only fitted on 3rd crankshaft bearing |

| q | Oil groove faces outwards |

| q | Note location |

| q | Measuring axial clearance of crankshaft → Chapter |

| 10 - | Bearing shell |

| q | For cylinder block (with oil groove) |

| q | Renew used bearing shells |

| q | Install new bearing shells for the cylinder block with the correct coloured markings → Fig. |

|

|

| Letter on cylinder block | Colour coding of bearing | |

| R | = | Red |

| G | = | Yellow |

| B | = | Blue |

|

|

| Letter on crankshaft | Colour coding of bearing | |

| R | = | Red |

| G | = | Yellow |

| B | = | Blue |

|

|