| –

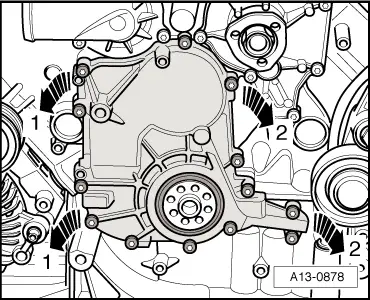

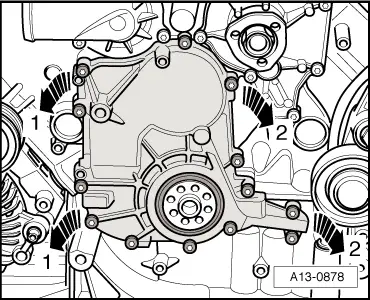

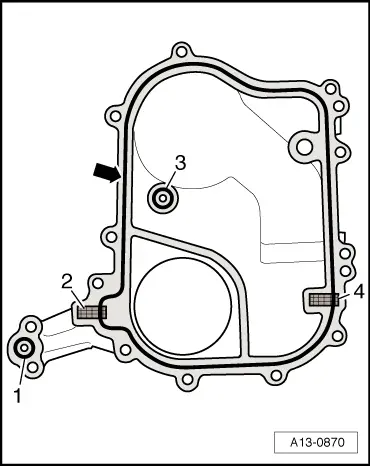

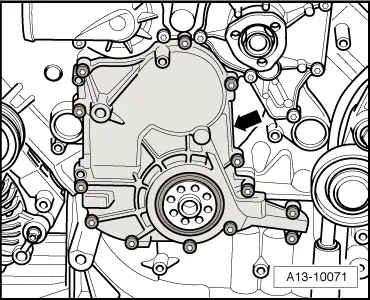

| Pull off front sealing flange (right-side first -arrow 1-, then left-side -arrow 2-). |

| –

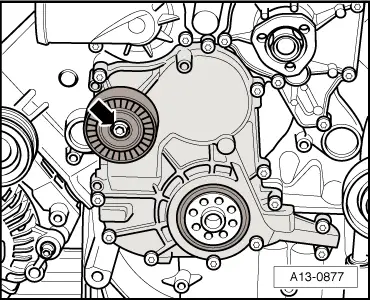

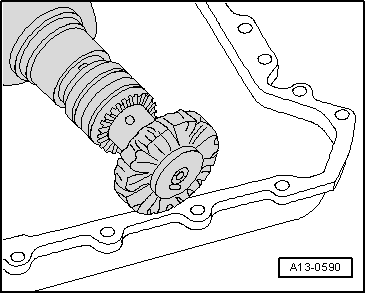

| Drive out oil seal with sealing flange removed. |

Note | t

| Renew gaskets, seals and O-rings. |

| t

| Hose connections and hoses for charge air system must be free of oil and grease before assembly. |

| t

| To ensure that the charge air hoses can be properly secured at their connections, spray rust remover onto the worm thread of used hose clips before installing. |

| –

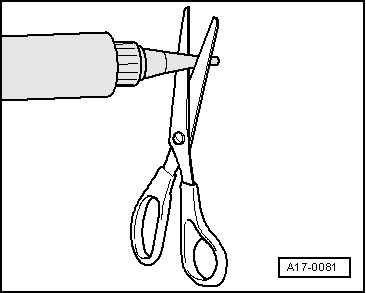

| Remove old sealant from grooves in sealing flange and from sealing surfaces. |

|

|

|

Note

Note

Note

Note

WARNING

WARNING