| –

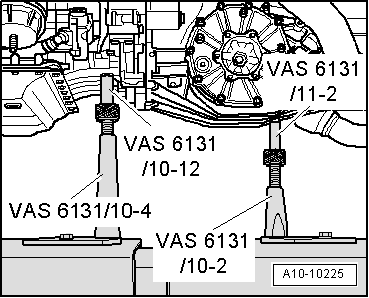

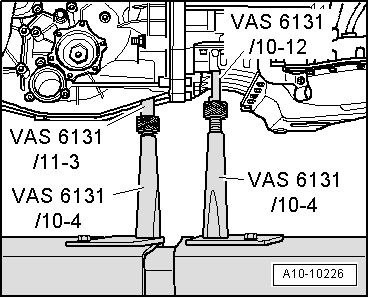

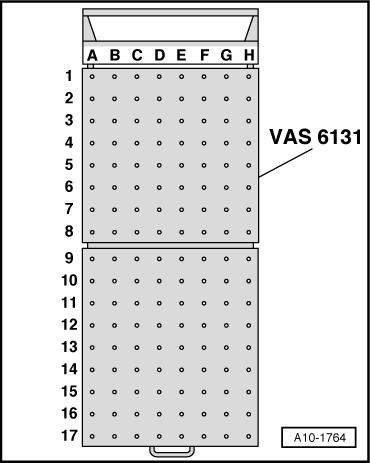

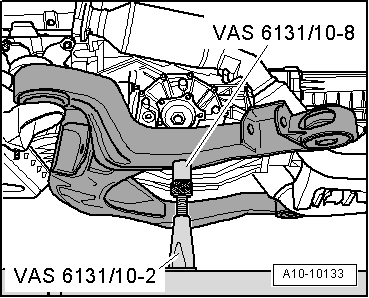

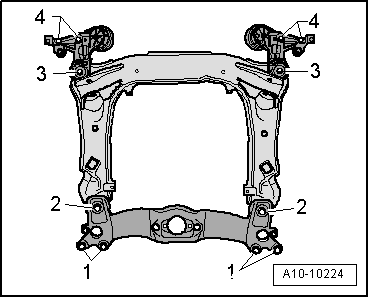

| Raise subframe via scissor-type assembly platform -VAS 6131 A- until subframe makes contact with body. |

| –

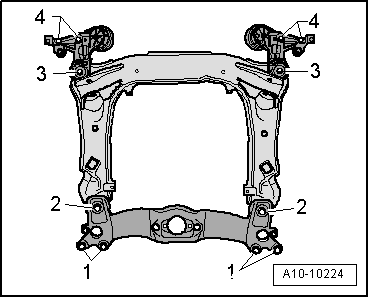

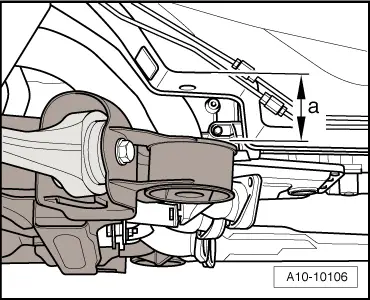

| Adjust the subframe, consoles for engine mountings and tunnel cross member according to the markings made on the longitudinal members during removal. |

| –

| Only tighten bolts for subframe, consoles for engine mountings and tunnel cross member to the specified torque (do not turn further); tighten bolts to final setting only after performing wheel alignment check → Rep. Gr.40. |

WARNING | The vehicle must not be driven at this stage. |

|

| –

| Install guide links, track control links and suspension struts → Rep. Gr.40. |

| –

| Align exhaust system so it is free of stress → Chapter. |

| –

| Install hydraulic pressure line for power steering → Rep. Gr.48. |

| –

| Observe notes on procedures required after connecting battery → Rep. Gr.27. |

Caution | Do not use a battery charger to boost starting. There is danger of damaging the vehicle's control units. |

|

| –

| Before starting engine, top up hydraulic fluid in power steering reservoir → Rep. Gr.48. |

Note | The power steering pump must not be run when dry. |

Note | t

| Drained-off coolant may only be used again if the original cylinder head and cylinder block are re-installed. |

| t

| Contaminated or dirty coolant must not be used again. |

| –

| Adjust subframe and the two consoles for engine mountings → Rep. Gr.40. |

| –

| Fit front wheels and perform wheel alignment → Rep. Gr.44. |

WARNING | Tighten bolts for subframe to final setting after performing wheel alignment check. |

|

Note | t

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricants such as engine or gearbox oil may be used, but do not use lubricants containing graphite. |

| t

| Do not use degreased parts. |

| t

| Tolerance for tightening torques ± 15 %. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note

Note

Note Note

Note Note

Note

WARNING

WARNING Caution

Caution