A4 Cabriolet Mk2

| Removing timing chains from camshafts - vehicles from 03.2007 onwards |

| Special tools and workshop equipment required |

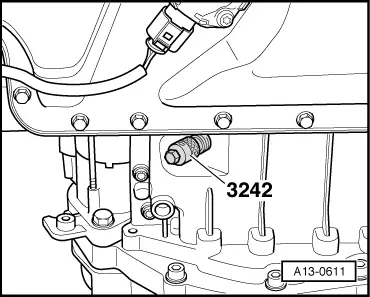

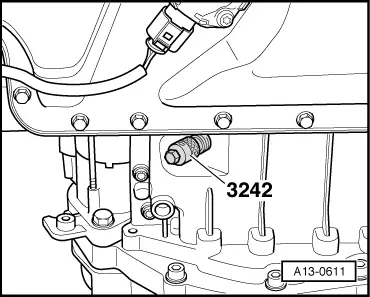

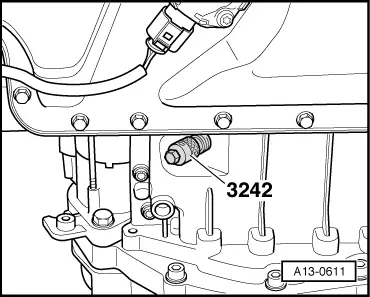

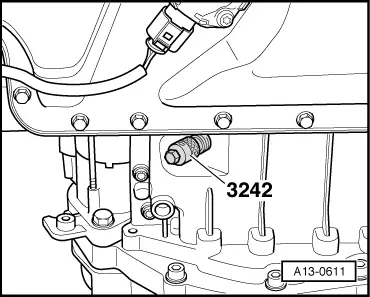

| t | Locking pin -3242- |

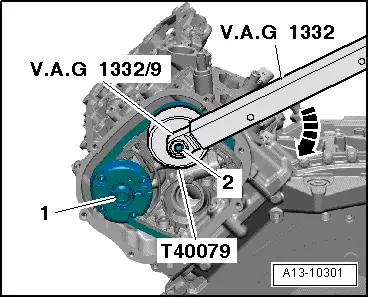

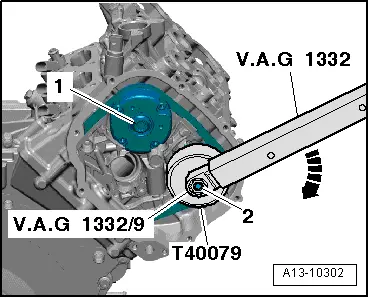

| t | Torque wrench -V.A.G 1332- |

| t | Socket -V.A.G 1332/9- |

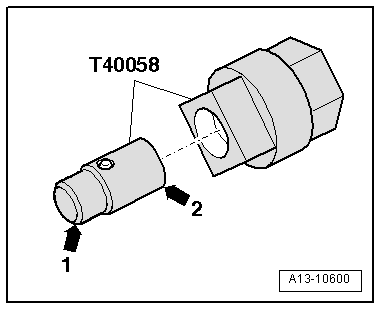

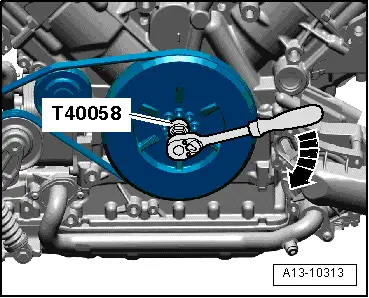

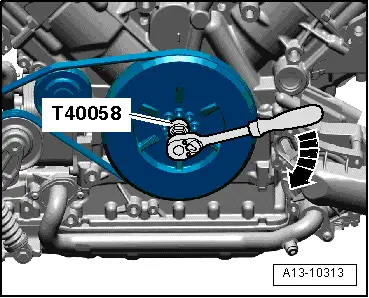

| t | Adapter -T40058- |

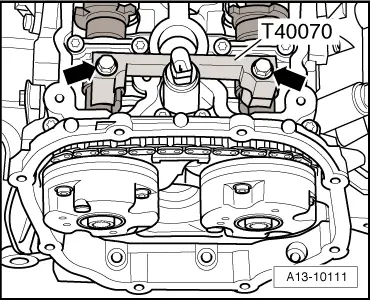

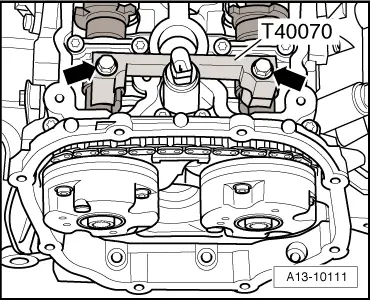

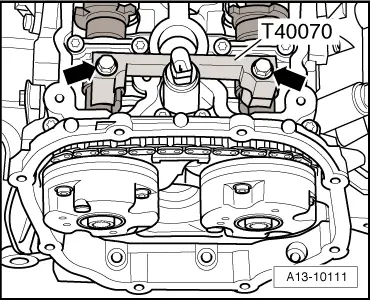

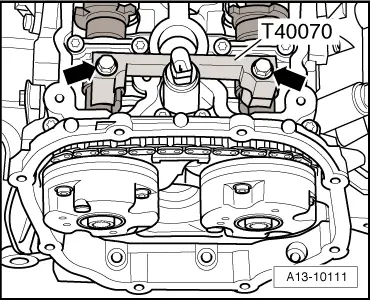

| t | 2x Camshaft clamp -T40070- |

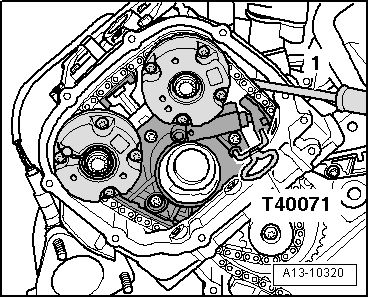

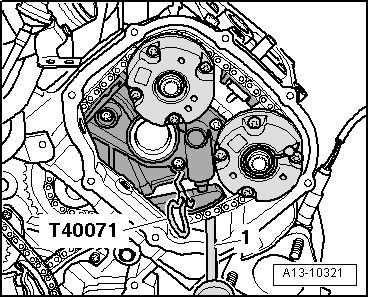

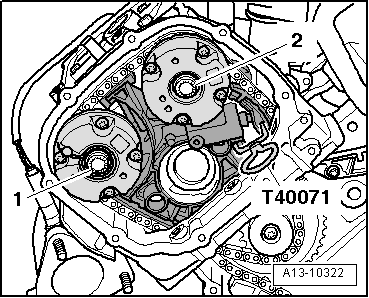

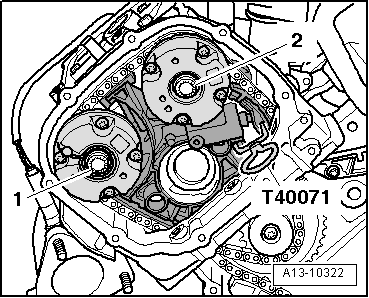

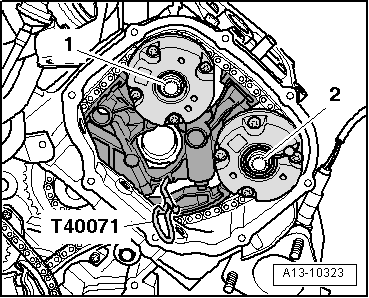

| t | 2x Locking pin -T40071- |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Caution

Caution