| –

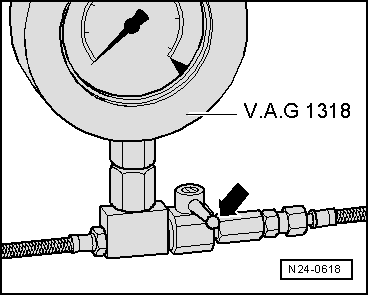

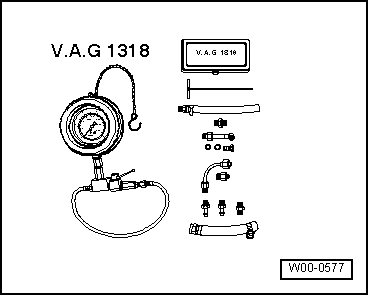

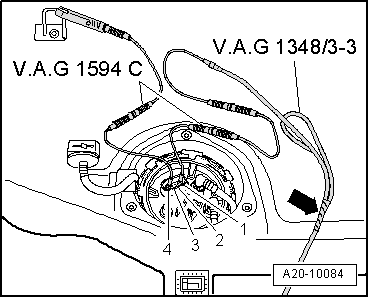

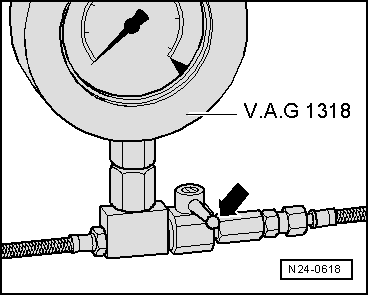

| Close cut-off tap on pressure gauge. Lever is at right angle to direction of flow -arrow-. |

| –

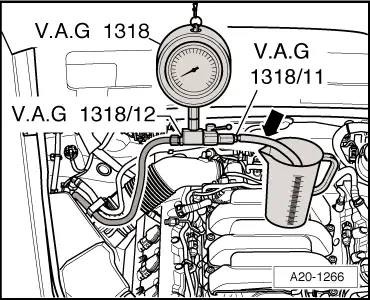

| Press switch on remote control until pressure gauge shows no further increase in pressure. |

| l

| Specification: approx. 6 bar |

| If specification is not obtained: |

| Checking residual pressure |

| –

| Check leak-tightness and residual pressure by watching the drop in pressure on the pressure gauge. |

| l

| After 10 minutes pressure should still be at least 3.75 bar. |

| If the residual pressure drops below 3.75 bar: |

| t

| Check union between pressure gauge and fuel line for leaks. |

| t

| Test pressure gauge for leaks. |

| t

| Check fuel lines and their connections for leaks. |

| t

| Renew fuel filter with integral fuel pressure regulator → Rep. Gr.20. |

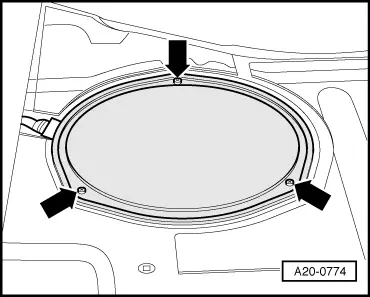

| Assembly is carried out in the reverse order; note the following: |

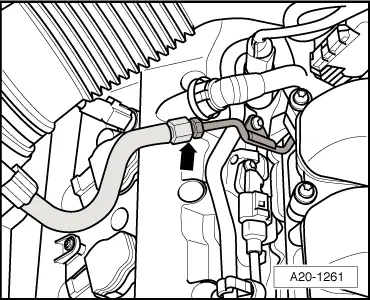

Note | Before removing the pressure tester, release the fuel pressure by opening the cut-off valve. Hold a container under the connection. |

|

|

|

Note

Note

WARNING

WARNING