| –

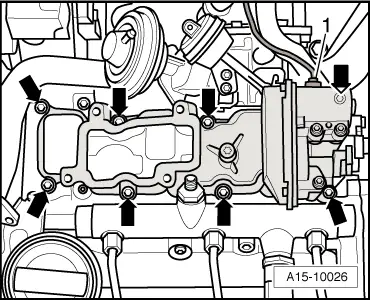

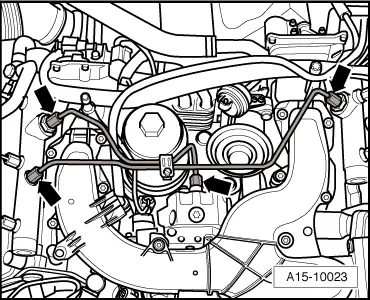

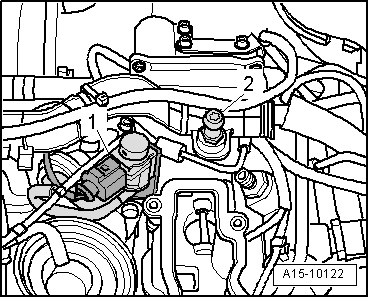

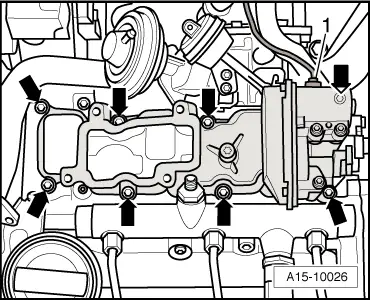

| Unplug electrical connector -1- at intake manifold flap 2 motor -V275-. |

| –

| Push coolant bleeder pipe to one side and take out bottom section of intake manifold (left-side) together with intake manifold flap motor. |

Note | Block off intake ports in cylinder head with a clean rag. |

| Installation is carried out in the reverse order; note the following: |

Note | –

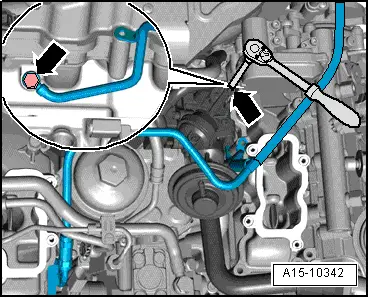

| Fit banjo bolt for coolant bleeder pipe with a new seal and screw in 2 … 3 turns, before installing left-side intake manifold (bottom section). |

| –

| Install mechanical exhaust gas recirculation valve → Rep. gr.26. |

| –

| Install intake manifold (top section) → Chapter. |

Note | t

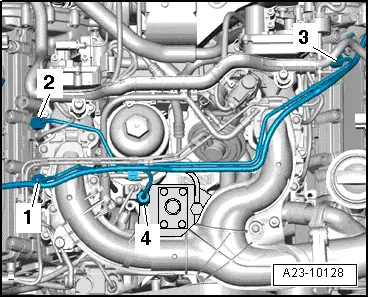

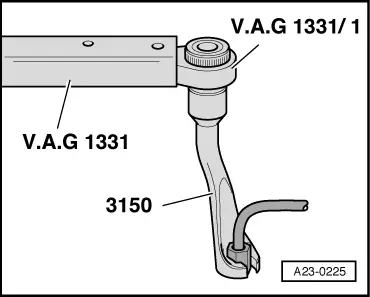

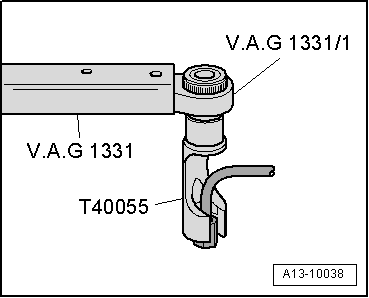

| Note identification marks for cylinder allocation when re-installing high-pressure pipes. |

| t

| The high-pressure pipes can be re-used after performing the following checks: |

| t

| Check taper seats of high-pressure pipes for deformation and cracks. |

| t

| The bore of the pipe must not be distorted, restricted or otherwise damaged. |

| t

| Corroded pipes must not be used again. |

| –

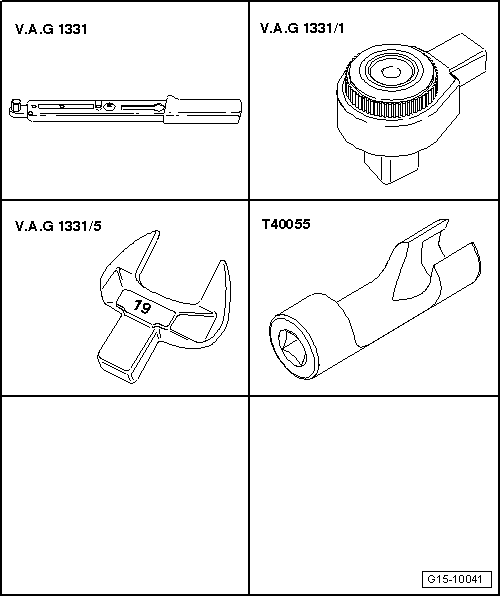

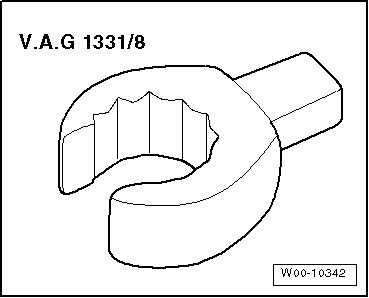

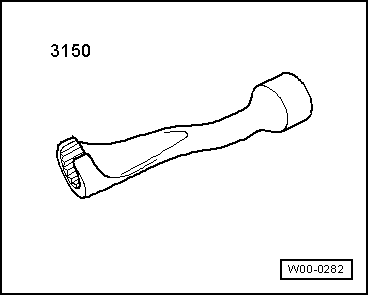

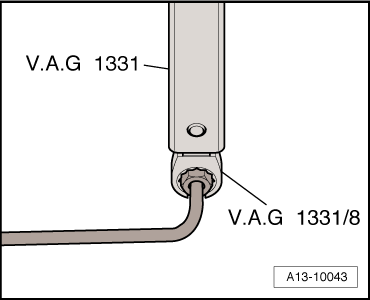

| Lubricate threads of union nuts with fuel. |

| –

| Tighten union nuts on high-pressure pipes hand-tight initially. |

| –

| Ensure that high-pressure pipes are not under tension. |

|

|

|

Note

Note Note

Note Note

Note

Caution

Caution