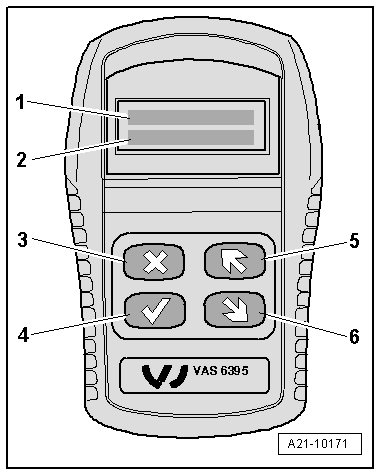

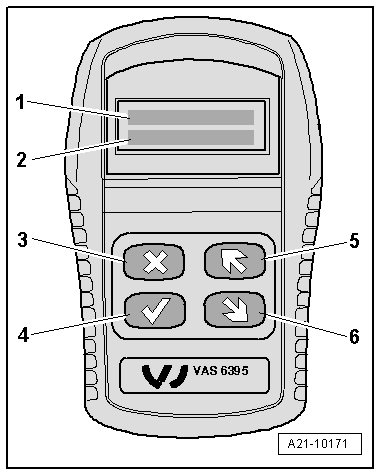

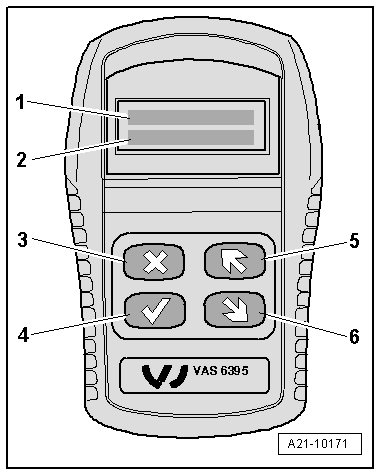

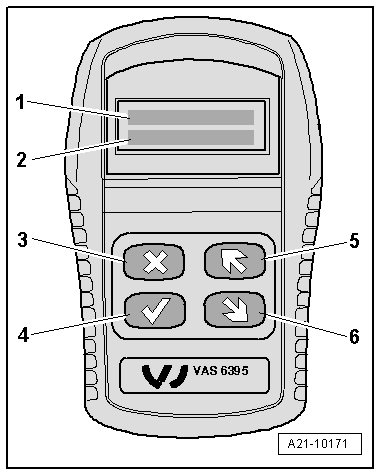

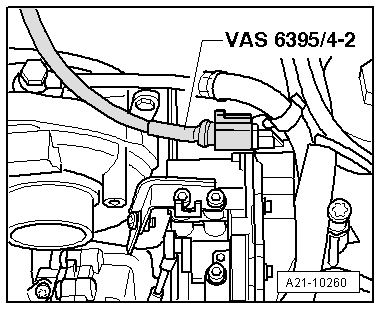

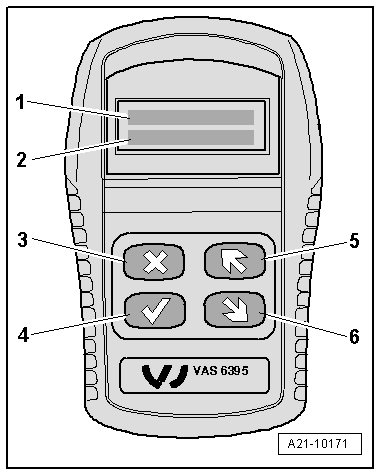

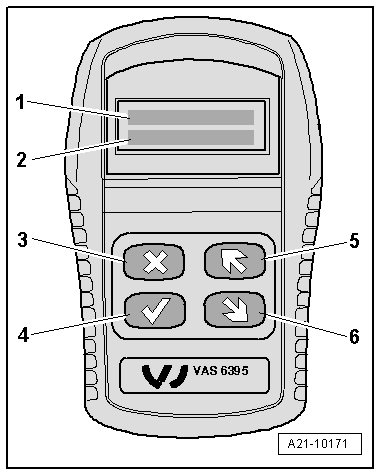

| Checking software version of tester -VAS 6395/1-: |

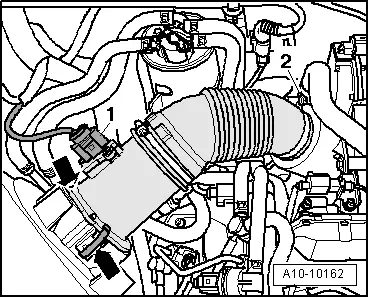

Caution | Risk of damage to intake manifold flap motor. |

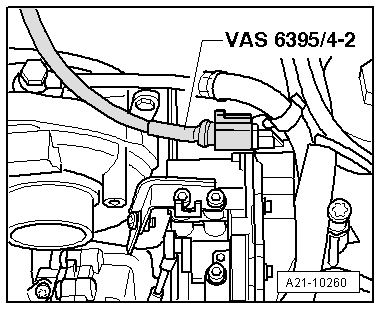

| Before continuing, check whether the correct software version is loaded in the tester -VAS 6395/1-. To do so, proceed as follows: |

|

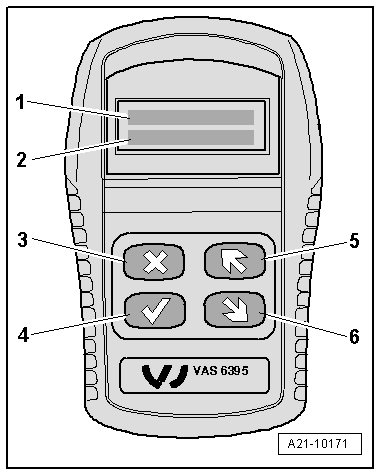

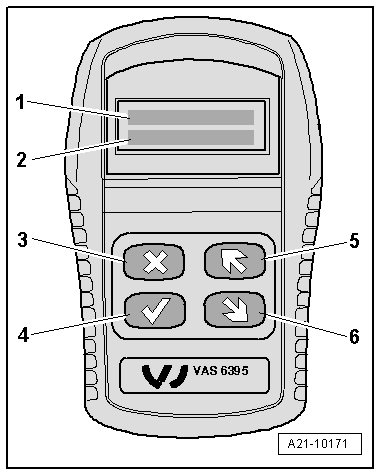

| Display on -VAS 6395/1- (2 seconds after connecting to power supply) if correct software version is loaded: |

Note | t

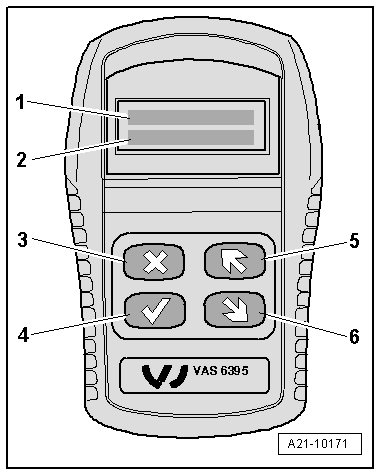

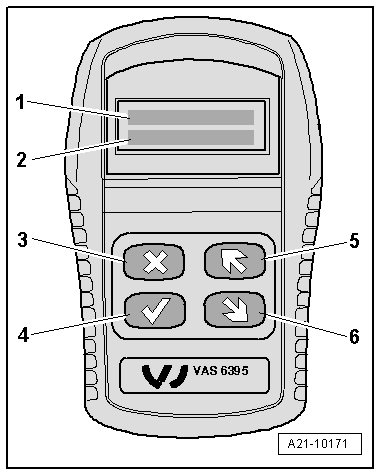

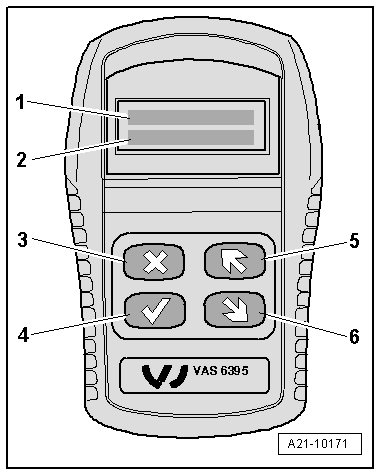

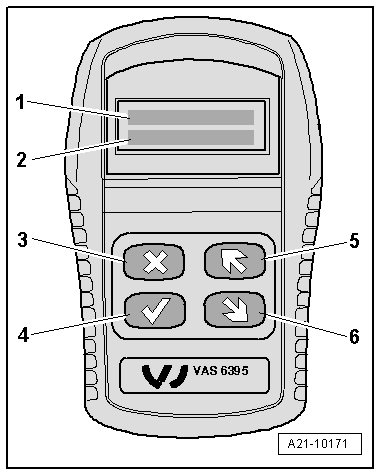

| If the following appears on the display, an incorrect software version has been loaded: |

| t

| If this is the case, download the correct software version from the „Audi ServiceNet“ under „Workshop Equipment“. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution