| Front and rear hydro-bushes (continued) |

| –

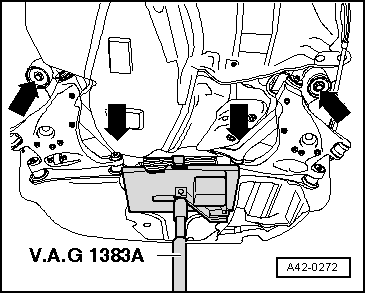

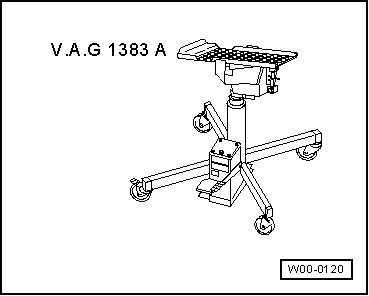

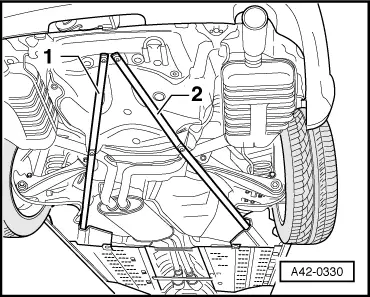

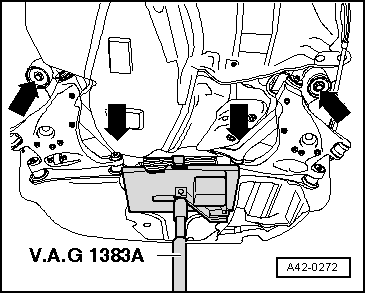

| Apply engine/gearbox jack -V.A.G 1383 A- with universal gearbox support -V.A.G 1359/2- and a suitable wooden block to subframe/final drive (illustration shows vehicle with front-wheel drive). |

| –

| Wind strap around subframe/final drive. |

Note | t

| If a front hydro-bush is being renewed, loosen only the front subframe bolts. |

| t

| If a rear hydro-bush is being renewed, loosen only the rear subframe bolts. |

| t

| If a further subframe bolt is loosened (front or rear), wheel alignment must be performed following installation. |

| –

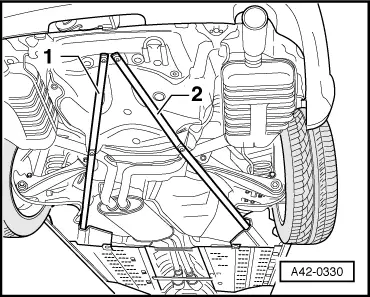

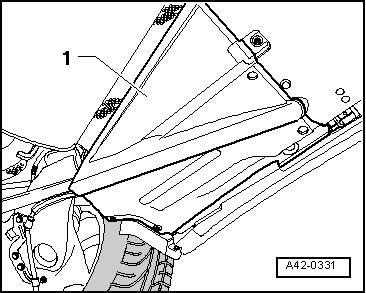

| Loosen front or rear subframe bolts. |

| –

| Carefully lower subframe approx 5 cm. |

| –

| Only remove those subframe bolts where the hydro-bush is to be renewed. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note