A4 Cabriolet Mk2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

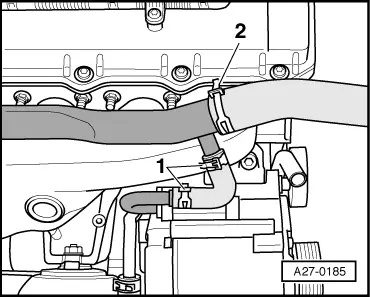

| Component | Nm |

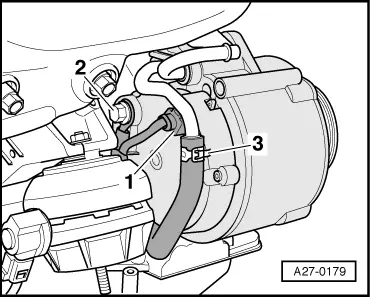

| Coolant pipes to alternator | 9 |

| Terminal 30/B+ to alternator | 16 |

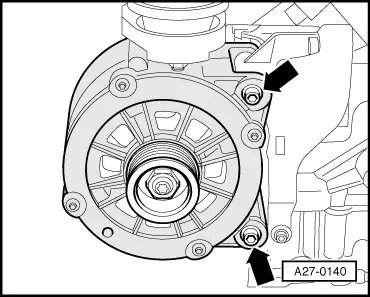

| Alternator to engine | 22 |

| Tensioning roller to engine | 22 |

WARNING

WARNING Caution

Caution