A4 Mk1

|

Anti-lock brake system (ABS) Bosch 5.0

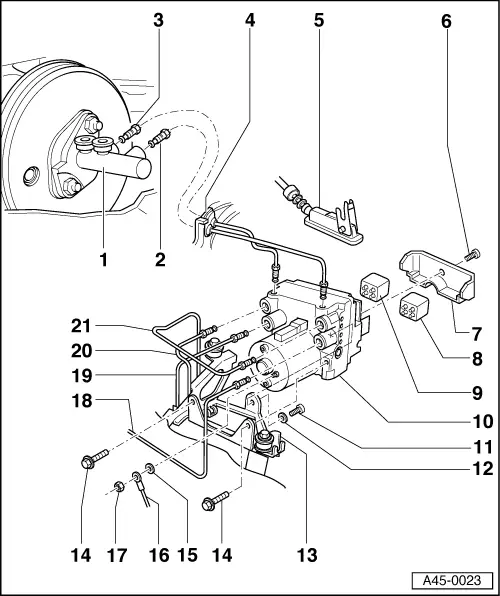

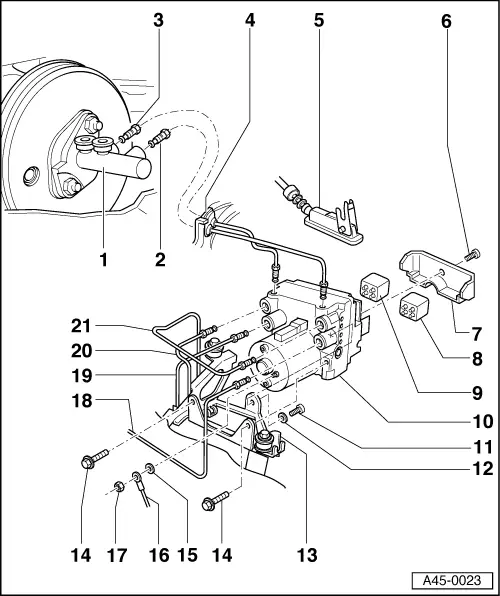

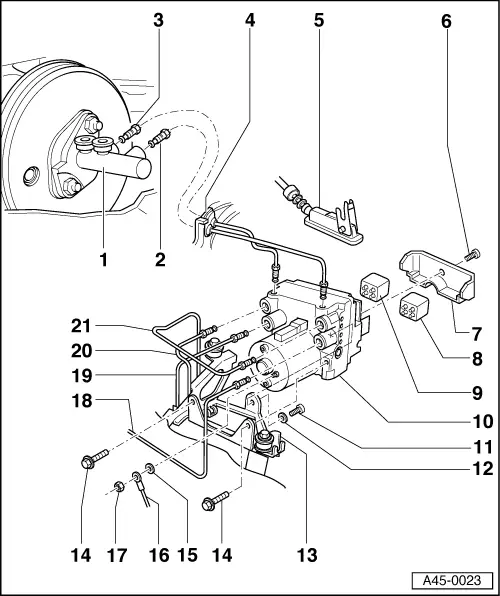

Hydraulic unit and brake pipes

|

|

|

|

The tightening torque for all brake pipes on the Audi A4 is 15 Nm.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

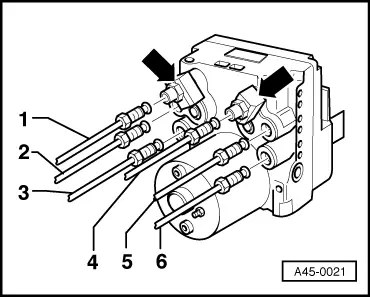

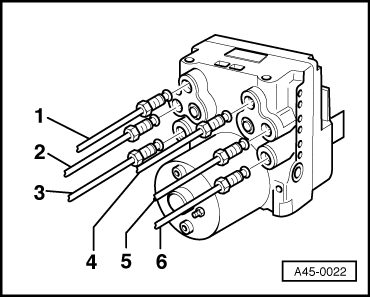

→ Fig.1 Hydraulic unit for ABS/EDL FWD models and also for ABS/EDL/TCS FWD models: brake pipe connections 15 Nm

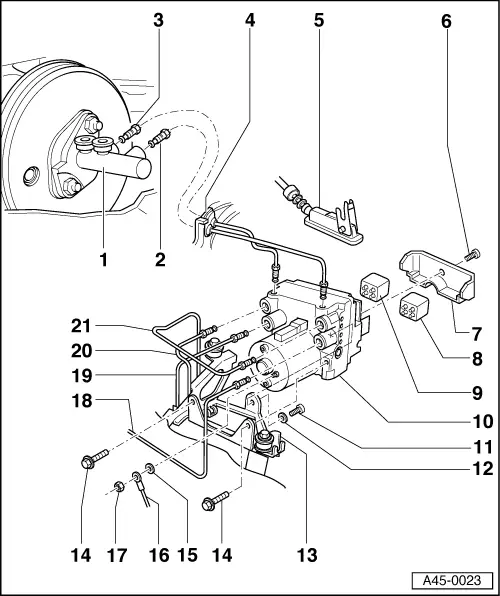

Note: The pressure dampers are not fitted to vehicles with 4WD and EDL suction control (05.95 onwards) => Fig.2 EDL suction control minimises control noises. The working range of the pressure limiting valve in the hydraulic unit is raised from 90±25 bar to 170±25 bar. |