-

‒ → Slide propshaft with assembly device to rear onto stop.

-

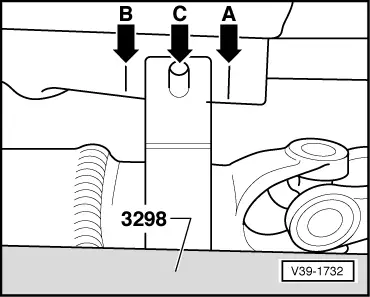

‒ Mark position of centre mounting on body -arrow A-.

-

‒ Push the propshaft with the assembly device forward as far as it will go.

-

‒ Mark position of centre mounting on body -arrow B-.

-

‒ Align propshaft -arrow C-.

-

‒ The centre mounting must be positioned centrally between the markings -A- and -B-

-

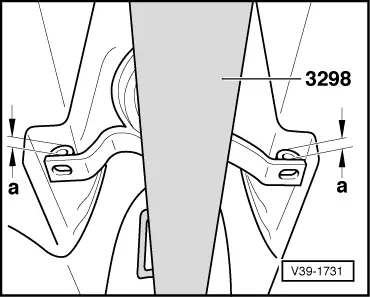

‒ Install securing bolts of propshaft centre mounting and previously determined shims and tighten.

-

‒ Remove assembly device.

-

‒ Install heat shield above propshaft.

The remaining installation steps are carried out in the reverse sequence - note the following points:

-

‒ Stress free alignment of exhaust system

=> 4-cylinder Engine (5-valve), Mechanics; Repair Group 26; Removing and installing exhaust system parts, Stress-free alignment of exhaust system

=> 4-cylinder Engine (5-valve turbo), Mechanics; Repair Group 26; Removing and installing exhaust system parts, Stress-free alignment of exhaust system

=> 4-cylinder Diesel Direct Injection Engine (TDI), Mechanics; Repair Group 26; Removing and installing exhaust system

=> 6-cylinder Engine (2-valve), Mechanics; Repair Group 26; Removing and installing exhaust system

=> 6-cylinder Engine (5-valve), Mechanics; Repair Group 26; Removing and installing exhaust system parts, Stress-free alignment of exhaust system

Tightening torques

|

|

|---|

|

Component

|

Nm

|

|

Propshaft centre mounting to body

|

23

|

|

Cross member to body

|

25

|

|

Nuts for clamp

|

40

|

|